What is a wood fire?

During the combustion of wood the organic molecules are decomposing into smaller pieces. Eventually those become gases, known as woodgas, and are the source of flames as they burn. The results of complete combustion are: heat, carbon dioxide (CO2) and water.

(read more)

Mixing

Woodgas is extremely combustible, explosive even, when it's hot enough and thoroughly mixed with fresh air. This mixing doesn't occur spontaneously, it is achieved because of the highly turbulent conditions generated by the batch box design in the port and riser.

(read more)

Mixing and turbulence in the Batch Box

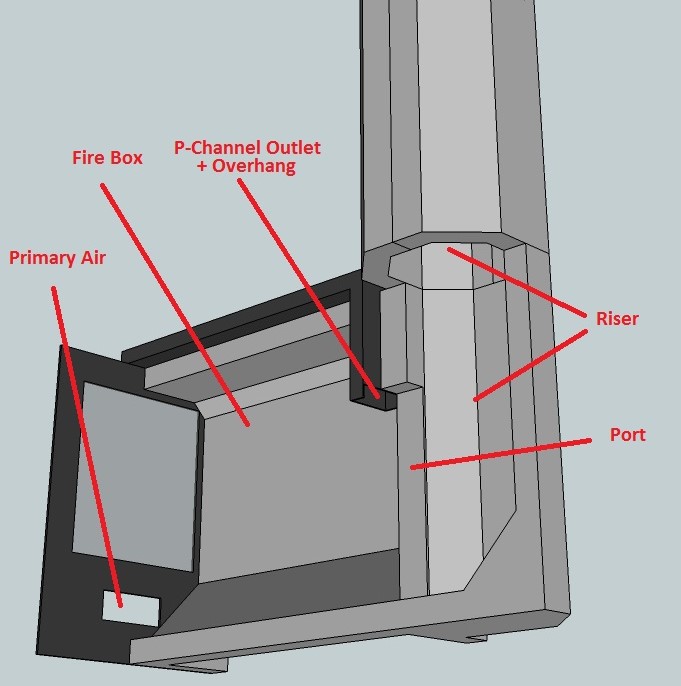

In the world of Rocket Heater builders the name of that short insulated internal chimney is called a "heat riser". In the Batch Box Rocket the tall and narrow opening at the bottom side of the riser is called the "port". The combination of riser and combustion chamber is called the "core". The way turbulence is invoked is significally different from a normal wood stove.

(read more)

Heat

Another evironmental factor is just as important as fuel/air mixing: maintaining high temperature during combustion. This shouldn't be taken lightly. During development temperatures as high as 1200 ºCelsius (2190 ºFahrenheit) have been measured in the riser. Higher temperatures result in cleaner combustion... and can also be a challenge for construction materials selected to be used!

(read more)

Cautions

It has been found experimentally that the respective ratios between the sizes of the combustion chamber, the port, the riser and the air intakes for good combustion are quite specific numbers. A relatively small change in dimensions that change the tested ratios could be enough to disrupt the correct functioning of the heater. Also, a proper chimney is very important.

(read more)

Exhaust gas measurements

The measurements that eventually led to the final Batch Box Rocket are done with a digital gas analyzer, the Testo 330-2. This device measures in real time during every "testrun" the temperature of the exhaust gases, the oxygen level (O2) and the content of carbon monoxide (CO). These measurements provided the necessary feedback so we could understand empirically how to improve combustion - not just a guess.

(read more)

Air streams in the port

Since 2012 a lot more is known about what the air flows in the port looks like and what their respective function is.

(read more)

How does wood burn in a fire?

The fire triangle shows the three things needed for a fire to start and keep going.

The complete combustion of wood (which is made up of hydrocarbons) results in the following: the hydrogen atoms combine with oxygen to make water vapour (H2O), the carbon atoms combine with oxygen to make carbon dioxide (CO2), and the maximum amount of energy is released.

These same end products are found in natural gas burners.

Lessen or remove one of the sides of the triangle then combustion will not be complete combustion but rather incomplete combustion. Water vapour and carbon dioxide are still produced, but two other products are also produced: carbon monoxide (CO), a colourless toxic gas and particles of carbon, which appear as soot and smoke. Additionally, the maximum amount of heat is NOT produced.

On the surface, burning wood does not seem too difficult, place some small dry branches with paper, put a match to it and the fire is started. Once we have the fire, to have it burn cleanly takes just a bit more thought and effort. We need higher temperatures than the few hundred degrees of a small fire and we need to 'keep it under control', not let it grow excessively. By insulating the combustion chamber and even more important, the heat riser, the heat generated from the fire is kept 'within the fire' maintaining a high combustion temperature wich aids in more complete combustion.

The result of these 'new conditions' (very high heat, 'Goldilocks air supply'-not too much, not too little, juuust right) will be a smokeless fire. Whilst being simple aims, a lot of effort was required to find the parameters presented here that achieve this smokeless fire. To understand why there is no smoke, it must be realised that smoke is simply unburnt fuel, nothing more, nothing less. In fact, up to 60% of the available energy of wood is found in these combustible gases. So smoke is not 'just a nuisance' which affects a large area in the outside environment, it is factually 'money up the chimney' in a very real sense. Money Up In Smoke!

Quite literally, apart from around one percent ash, the entire content of wood can be converted into heat**, and as such smoke is only an indicator of incomplete conversion of fuel into heat. These heaters, as described earlier, have very high temperatures of combustion, so the smoke is very hot in the combustion chamber and in the heat riser. We combine pre-heated air with that smoke which results in spontaneous combustion of the smoke. Even the rightly feared carbon monoxide -a deadly poison- is in fact simply unburnt fuel (recall above that in complete combustion CO is not a product of wood burning). CO has no odour of it's own, so when "town gas" which contained up to 8% CO was used for heat well into the twentieth century mercaptan (a foul smelling substance) was always added to the gas, simply to alert people to any leaks or unlit burners. The point remains though, CO is a fuel (and used as such in town gas) and all of the wood's energy content can be extracted if burnt correctly.

** Whilst this is strictly true, a few points must be understood to put this into a real world context. These heaters will not be used in a laboratory with pure oxygen, they will be used at home with ambient air. Even weather conditions will vary and influence the burn. Most importantly, all air dried wood will contain some moisture. This needs to be driven off before combustion of the wood can take place. To boil off water takes a tremendous amount of energy as shown below.

The graph shows how the temperature of water rises as energy is added. (it starts from below freezing point which we will ignore. Unless the wood you use is itself below freezing!) As energy is added (the horizontal axis), the temperature rises along the straight line C, for every 'bit' of energy added there is a corresponding rise in temperature which is why it is a straight line.

When the water reaches boiling point (100 ºC at sea level) it no longer gets any hotter (seen by line D, it is horizontal even though energy is still being put into the system) During this stage, the energy being absorbed by the water is not making the water any hotter, but rather is making the water change from 'liquid to gas', and this takes place with no change in temperature. Line E will ONLY begin once all of the water has become steam.

Unless we have a condensing boiler, that energy required to turn the water to steam is lost from the system, and into the atmosphere. So, in real world practice, these are some of the losses that do and will occur. The *very*important *point* to be taken from this is, NEVER burn anything other than dry wood. Now you know why.

The following video is a fine example of the flammability of smoke.

Mixing and turbulence

Strangely enough, wood itself does not burn. It is similar to petrol, petrol itself does not burn. If you are quick enough you can douse a match in liquid petrol. It is not recommended that you try it, as most likely the match will ignite the mixture of petrol vapours and oxygen just above the liquid petrol. Once that is understood, it is clear then that it is wood 'vapours' mixed with oxygen that are the substances that burn. Heat causes the chemical components in the wood to break down into smaller, flammable components which then combine with oxygen (in the presence of heat), in turn releasing more heat which causes the cycle to continue. A pure woodgas flame should be blue, hard to see in sunlight. Because there's also glowing carbon dust carried with the flame the colour is red, orange or yellow, the higher the temperature the lighter the colour. When there's a lot of gas in the flame and a tiny bit of carbon it could appear as yellow-purple.

Once it is understood that it is the substances released from the wood by heat that combine with oxygen, we can see that complete and thorough mixing of these substances with oxygen is needed for complete combustion. In practice this is the most important objective to achieve and the most difficult. A column of smoke rising from a fire will most likely burn on its 'outer surface', the interface between the smoke (fuel) and the oxygen rich air. Inside the column of smoke there is very little oxygen hence no combustion. It finally leaves as smoke (unburnt fuel) because even though it eventually meets enough oxygen it has cooled enough that combustion does not occur. Recall that there are three conditions necessary for combustion, fuel, oxygen and heat.

The common method used in combustion heaters to induce this oxygen and fuel mixing is to inject fresh air (usually not pre heated) into the fire from multiple locations. A lot of air is needed for this conventional wood burning system, which is a serious disadvantage because it will lower the temperature of the fire, one of the three conditions needed for complete combustion. In metal stoves this cooling of the fire is not regarded as a disadvantage but rather an advantage, as the temperatures that can be reached from a wood fire are great enough that the steel, even stainless steel, will be destroyed in a surprisingly short time frame. The combination of an oxygen rich and carbon poor environment coupled with high temperatures will corrode the steel very rapidly. As a result, during every burn severe spalling at the metal surface will occur at the hottest spots.

The heaters described here are designed to maintain the hottest burn temperatures possible -far greater than metal heaters can withstand- and ensure proper mixing of the fuel gas and oxygen by methods described in the following section.

Mixing and turbulence in the Batch Box Rocket

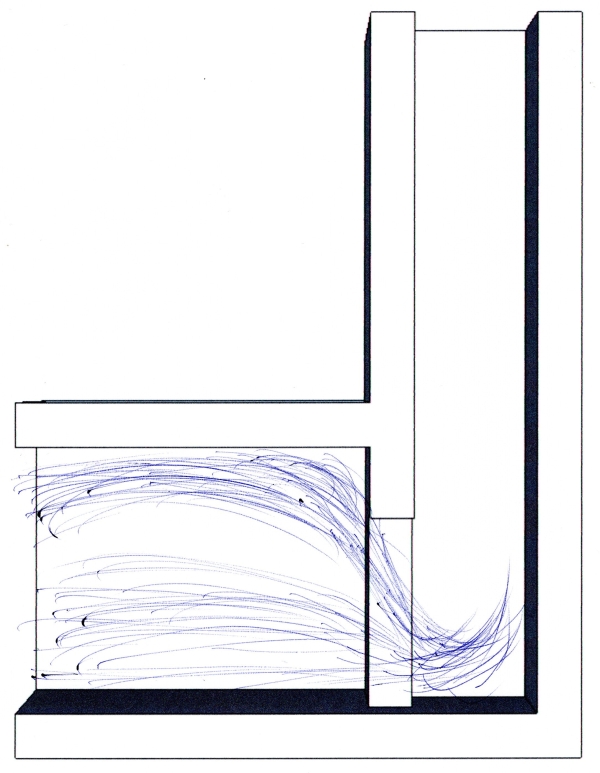

The mixing of wood gas and oxygen in the batch box heater is achieved by the carefully designed geometry of the combustion core and the correct positioning of both the primary and secondary air intakes. These critical dimensions will be given later. The arrangement of these building components is quite simple and shown in the 3D cutaway illustration below. The combustion chamber which is longer than it is wide vents to the rear, where a vertical insulated 'chimney' is placed. This is the heat riser referred to above. The function of the combustion chamber is naturally to combust the wood, the function of the insulated heat riser is to allow the final (and complete) combustion of any wood gas produced from the wood fire. From the preceding sections we now understand what is needed to have that complete combustion, fuel (the wood gas), heat (from the fire and from the combustion of wood gas itself. Note again that especially the riser is heavily insulated, ensuring as little heat as possible is lost from any combustion process) and oxygen.

Note particularly the connection between these two elements of combustion chamber and heat riser, a high and narrow opening between the two. This is known as the 'port'. It is actually 70% cross sectional area of the cross section of the heat riser (the cross sectional area of the heat riser is one of the 'standard dimensions' in these heaters, namely a dimension from which other dimensions can be scaled). The port itself is 72.34% of the riser's cross section area, but due to the overhang of the secondary air p-channel this is reduced to 70%. This sudden narrowing in the path of the gas stream has a very important function, as the *same* amount of gas is flowing through the system at all times, when it comes across (or passes through) a narrower opening, it must then speed up at that point (remember, the same amount of gas is passing through at all times and all places). The result of that speeding up at that exact point is that the pressure at that point lowers.

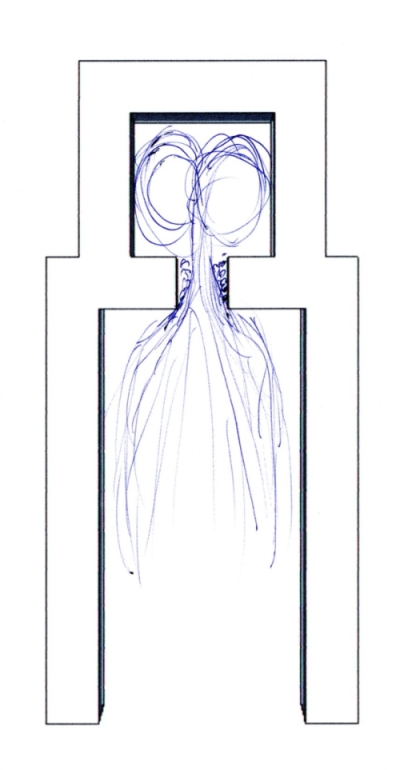

The picture above shows a cut-away view of 1/2 the combustion chamber and the lower heat riser.

Now referring to the diagram, secondary air is delivered through a hollow tube (shown in black at the top of the combustion chamber) connects the external air directly to the point of lowest air pressure in the system, the opening of the port.This form of secondary air intake is known as a P-channel and is one of the early innovations I created that noticeably improves combustion.

This then causes air (or more properly oxygen) to be introduced into the gas stream as it enters the port. As can be imagined, we now have the three conditions needed for combustion, fuel, heat and oxygen. The wood gas is already extremely hot, there is an awful lot of heat in this location, all we need now is the final complete mixing of the oxygen and wood gas. One last point to be noted now, as the secondary air being introduced into the port has to pass through the steel pipe located on top of the fire, it has been pre-heated on it's journey to the port. This pre-heating of incoming air assists in keeping the combustion temperature high.

The thorough and complete mixing of the wood gas and oxygen occurs as the mixture passes through the narrow port and into the heat riser behind. As the gas flow speeds up through the restriction of the port and then slows down abruptly when it reaches the *larger* space behind the port, a massive pile up in the gas flow occurs as the still fast moving molecules passing through the port slam into the suddenly slowed molecules in front of them. This creates considerable turbulence and is continuous as long as the velocity of the gases are higher in the port than in the riser, the large majority of the burn time. These conditions cause the flammable gases to mix into a swirling double vortex in first a horizontal plane and then an ascending double corkscrew as it rises within the heat riser as it exits the system.

The ascending double corkscrew forces the gases to take a much longer path (and hence take longer time) than if they were to go straight up. That this longer travel occurs within a well insulated, extremely hot environment allows the mixed fuel and oxygen to readily combust.

The speeding up of gases as they pass through a restriction is known as "the venturi effect", a law of physics first described by Daniel Bernoulli in the 18th century. The highly chaotic conditions created by this arrangement can be seen in this short video filmed looking down the heat riser and directly at the exit of the port, where the massive pile up occurs and the double vortex/ascending corkscrew is formed.

The rather unique way these heaters create the turbulent conditions required for complete mixing of oxygen and fuel has other favorable results for combustion efficiency. The metal box heaters' blunt sledgehammer approach means lots of air was introduced. This extends the life of these heaters but as noted reduces efficiency. Because the preheated secondary air in the batch box heater is introduced into the best injection point for complete mixing to occur, we do not need anywhere near the same amount of introduced air as metal heaters. So the total cross section area of the combined air intakes is smaller than would be expected in a normal box stove. These smaller than expected air inlets are perhaps even more surprising when it is seen how quickly the fuel is consumed in these heaters.

One last explanation of why 'excess amounts of cool air' is contrary to good efficiency. The essential component in air for combustion is oxygen. Any other component in air is only a passenger, it contributes nothing to the combustion but only serves to cool the fire (they are known as ballast gases. Just as on a ship, ballast is only excess weight and not cargo). As you can see these heaters, by careful use of geometry and taking advantage of natural laws, we introduce the right amount of oxygen to the exact spot required for complete mixing and combustion.

Maybe we can extend this idea of 'goldilocks air'. Not only is it not too much or too little air, juuust right, it is also in juuust the right place.

These heaters generate a typical noise, a low rumbling (but strangely comforting) sound. In fact, it is this characteristic sound found in all of these variants of heaters that gave them the name 'Rocket Stoves'. The short video that follows gives an indication of this characteristic sound, this particular example is in a metal housing so has more of a 'ring' to it, builds that employ masonry or brick housings the timbre changes to a less ringy, lower rumbling sound that is not offensive at all.

Lots of heat

Both the firebox and heat riser are insulated heavily, with particular emphasis on insulation of the heat riser (where the temperatures can be the greatest). This enables the whole to more quickly reach optimum operating temperature and enhances the combustion of the woodgas/oxygen mixture which is of course the basis of heater efficiency.

Important point

It is important to realise that the shapes and dimensions of the combustion unit are quite critical. Variations from these are effectively untested. Your proposed variation may have hit upon a winner, but without testing no-one will ever know). The specific values of 'tightness' of these ratios of design dimensions and ratios is quite logical, they are responsible for what's going on in there.

To achieve the goals of this heater (smoke free highly efficient combustion that can be followed and built by others) it is important that the developed and tested dimensions are followed quite closely.

A proper chimney is required, a chimney is the 'engine' of any wood combustion heater, and is the motive force that creates sufficient draft for clean combustion. As discussed above, the air inlets are smaller than 'expected' and as such are perhaps more easily affected by variations from the design given here. Ratios of the design are to be found in the "Building" section. When the flue temperatures rises (and hence the draft) the air inlet can be decreased, or larger pieces of wood used. Larger more 'chunky' pieces of wood have less surface area than a similar weight of 'finely divided' wood.

These heaters burn the fuel load without the need for restrictions in the air supply or any other measure used to 'slow the burn down for longevity' as done in conventional wood stoves. It should be clear by now that for maximum efficiency and cleanliness of the burn those types of incoming air restriction measures only harm that goal. And so to harness or profitably utilise the heat created we need a large radiating surface or a sufficiently large mass to absorb and slowly release the stored heat. These different approaches will be covered later.

A curious phenomenon of these heaters is the time taken to burn a load. It turns out (rather counter-intuitively) that full load of wood combusts in about the same time as a half load of wood (or other ratio), from lighting to glowing ember phase. So it can be seen that a full load of wood delivers a surprisingly large amount of energy in a given time. Hence we need ways to harvest this heat which will be discussed in the following pages.

Results

In the last four years (2012 thru 2016) I've executed hundreds of runs on the core presented here, and am satisfied a stable dependable combustion heater has been designed. The Testo 330-2 is a gas analyzer which measures the flue output and from that data calculates the efficiency of the burn, and can be connected to a computer as I have done to generate its own line diagram and spreadsheets.

The test shown in the above diagram has been run in a warm heater, as can be deduced by the starting temperature (measured in the flue outlet, in degrees Celsius, represented by the blue line). As mentioned earlier, a 'hot' (already up to working temperature) flue will have a correspondingly strong draw, and so in this run the fire developed quickly. During the run the oxygen level (green line) dropped below what I consider as the border between optimum and non optimum (6% O2). Below that figure runs the chance of higher (purple line) CO outputs (as insufficient oxygen is present). That did not happen in this case as can be seen, so whilst that risk is present it is clear that excellent burns can still be obtained. From all of the earlier discussion given on combustion it can be seen/understood that the oxygen levels, and the flue temperature are directly linked to the efficiency of the burn. The efficiency is shown by the red line.

When the oxygen content does not drop below 10% with a correspondingly low flue temperature of 80 ºC (176 ºF) the efficiency will be higher than shown in the above graph. However lower exhaust gas temperatures means less draft and can have repercussions on combustion because of lower flow velocity through the system.

These graphs that show the inter-relationship between the various parameters of the burn are a graphical way to understand the 'Important Point' made above, that it is doubtful that a departure from the descriptions given here will result in a more optimum heater. Of course it IS possible, but highly unlikely. The interactions within the heater are very complex, and any change has to be evaluated by actual measurement by testing similar to that shown here.

The above graphic is of course a very nice one and for this reason not very representative. A somewhat more normal looking diagram which is generated during development in 2012 could be this one:

Comparing the graphs we can learn a few things (like why the Testo is absolutely essential in knowing exactly what happens during a burn) and see how this burn is more representative than the "cherry picked" stellar example just above. As you can see the extremely low CO levels (pink line) which indicate complete combustion does not occur quite so soon as before, nor does it last as long. Also observe that the Oxygen level (green line) does not go as low, but is still at a very nice level. The oxygen measurement is known as 'excess O2'.

The above is the graphical representation of a very ferocious burn, roaring, joggly and bumpy and occasionally also smoking. Recent developments came to a close with much better results, this will be discussed in the "Core designs" chapter.

Working of the air streams

August, 2020

Since the start of development in 2012, how the batch box rocket works has become much clearer. That the BBR has good scalability (readily enlarged or decreased in size) suggests the presence of underlying fundamental principles.

Eight years later there are some conclusions to be drawn, supported in some respects by people who better understand aerodynamics than ordinary mortals. Those conclusions are based on observations made by multiple builders and developers on different continents. In no case are the following conclusions scientifically substantiated, they are only plausible.

1# The current explanation of why such a hot and fierce fire can be attained is attributed to the pressure difference between the front and rear of the fire chamber.The port acts as a venturi, explained earlier in this chapter. In that venturi the air velocity is greater and the pressure correspondingly lower than at the front where the air enters. That differential pressure is always greater than the draft of the chimney, the port acts as an amplifier. The larger the difference, the brighter the fire, similar perhaps to a fan blown fire. That is also why the time that elapses from ignition to the glowing phase with half a batch under the same conditions is almost the same as with a full batch. That full batch produces a larger fire, a stronger negative pressure in the port and therefore also a faster combustion. It is not the case that a quarter of a load also takes as long, apparently there is a limit. A very hot and clear fire delivers the most complete combustion.

2# When the riser is viewed from above, it is clear that the stream of fire through the port appears to be narrower than the port itself. The speed of that flow is also greater than what can be expected based on what is visible in the firebox. This has to do with the square edges of the port. This point was discussed extensively with Dr. Larry Winiarski * during a workshop in Warsaw, July 2015. Some builders had already chamfered or rounded the edges of the port a number of times, in an attempt to make it more attractive. If that chamfer was large enough, about one-third or more of the port’s depth, it was sufficient to destroy complete combustion in almost all cases. The end result is black smoke from the chimney, just because of the all too smooth curves.

Possible explanation of this phenomenon: sharp right-angle edges cause a lot of small turbulence along the walls of the port. That wall turbulence also slows down the flow along the walls. In the middle of the port the speed remains high, which makes the current seem narrower to the eye. Due to the delay on the left and right, the flow splits easily and the two flows curl, creating the double vortex. The residence time in the hot riser is extended this way which allows more of the wood gas to combust.

Thus the port should always have two right angles and should open up in the center of the riser.

For example, it is tempting to build a sidewinder in such a way that the back wall of the firebox is flush with the wall of the port. This situation does not meet the conditions outlined above and the properties of the batch rocket may be worse as a result. If the port is not built in the center of the riser but on one side, a single vortex is created. The residence time in the hot environment of the riser then becomes shorter, which in turn affects the quality of combustion.

3# A well-functioning batchrocket shows a horizontal flame, especially at the beginning of the combustion when the afterburning starts. And that flame appears in the bottom half of the port while the top half is completely empty to the eye.

Especially in the early stages of development, some batchrockets were built where the port had the full height of the firebox rear wall. Even though the width was made smaller to compensate, the result was always bad to worse as opposed to using the currently common piece of wall above the port.

In addition, with open systems (see Applications) the phenomenon occurs that combustion without a door and without secondary air supply is still very good. Yield is lower but by not more than 4% or 5%. Also in this variant the flame tend to ignite very low in the riser.

The explanation for all three of the above phenomena probably lies in the flow of air passing over the fire towards the port. Because the air above the fire gets very hot, it flows unimpeded along the ceiling. At the rear wall, the current is bent down and accelerated by the venturi action as soon as it enters the port. The greater the air speed at that moment, the less easily the flow changes direction. Until the stream encounters some obstacle that forces it to go another way, the air through the openings between the pieces of fuel in the firebox together forms such an obstacle. The flames in the firebox are blown to the rear and the flow of air from above forces it down. In a closed system, a p-channel or floor channel provides additional air at exactly that location.

An open system takes advantage of this effect, allowing sufficient fresh and hot air to enter the port and riser in an aggressively turbulent environment. So it is clear that a port the full height of the firebox does not work properly, the hot air from the ceiling simply passes straight into the riser without creating any down-forcing turbulence. And lastly, this may also explain why an object like a piece of wood sticking into the port can destroy the desired complete combustion. The currents are disrupted and the aerodynamics of it all change completely. By withdrawing that piece of wood, the entire system will revert back to proper functioning again within a minute.

Please be aware that a heater with no door isn't recommended inside a house. Due to the fact that in essence it is an open fireplace, it could spill smoke inside the living room. Also, no door means the heater can't be closed which could be dangerous while people are asleep. In case the fire isn't completely out, deadly carbon monoxide could spill out of the heater due to weather changes for example.

*Larry Winiarski is widely regarded as the creator of the original rocket stove. Created as a more efficient alternative to traditional open fires in many developing countries and refugee camps where cooking is done on a wood fire.