Batch Box Rocket by Peter van den Berg

Batch Box Rocket by Peter van den Berg

is available under the Creative Commons Attribution-ShareAlike 4.0 International license

It has been decided to offer the information on this site free and without advertising. However, the provision of this information on this website does cost money which include hosting fees. Experiments which led to the results and the final designs presented on this website have also cost money. Including the purchase of a gas analyzer which need to be calibrated once a year in order to generate reliable results and being able to offer those to you.

Your donation is essential in order to continue this work and to maintain this site.

All heater cores are designed by Peter van den Berg, unless stated otherwise.

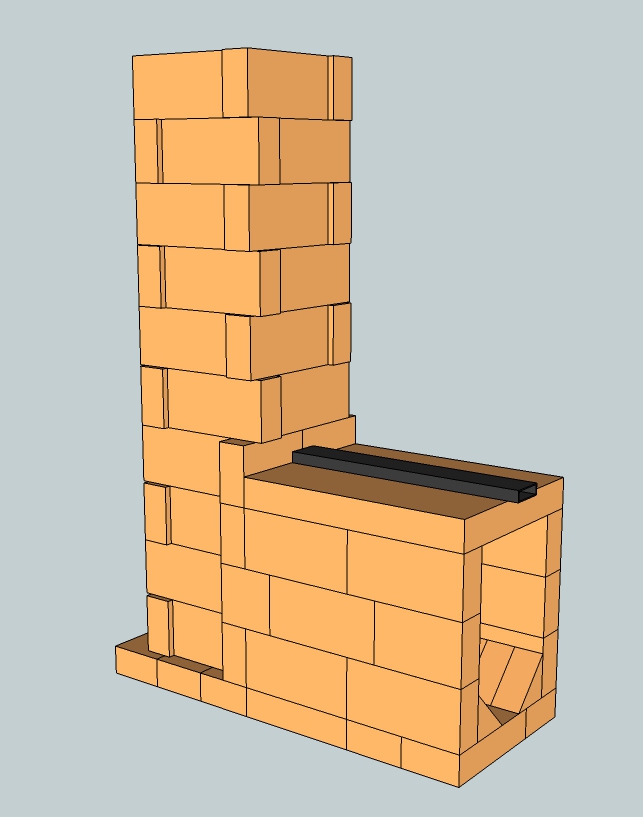

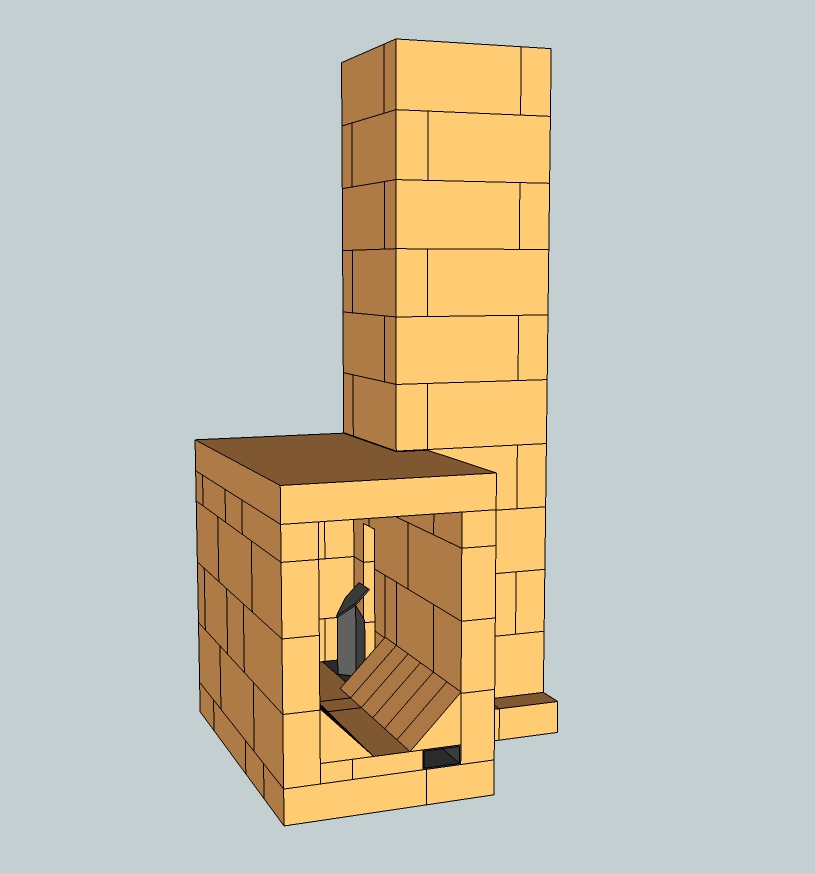

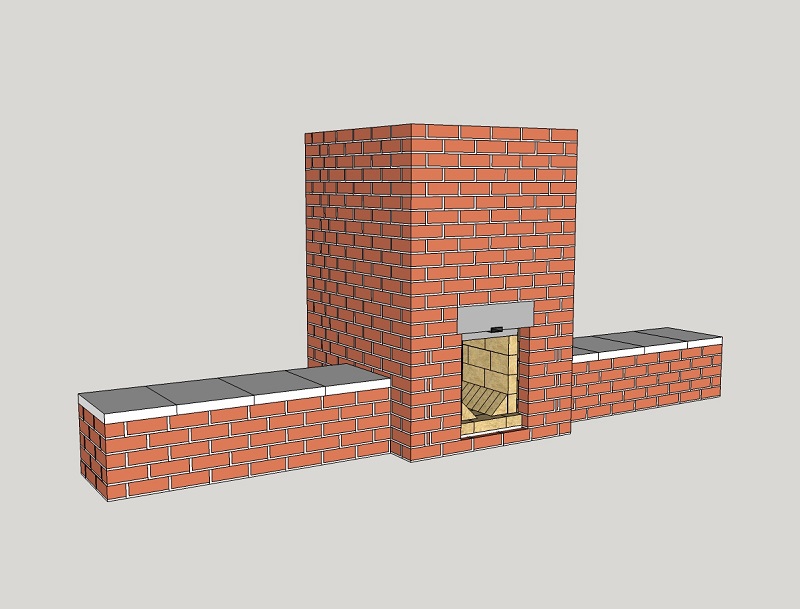

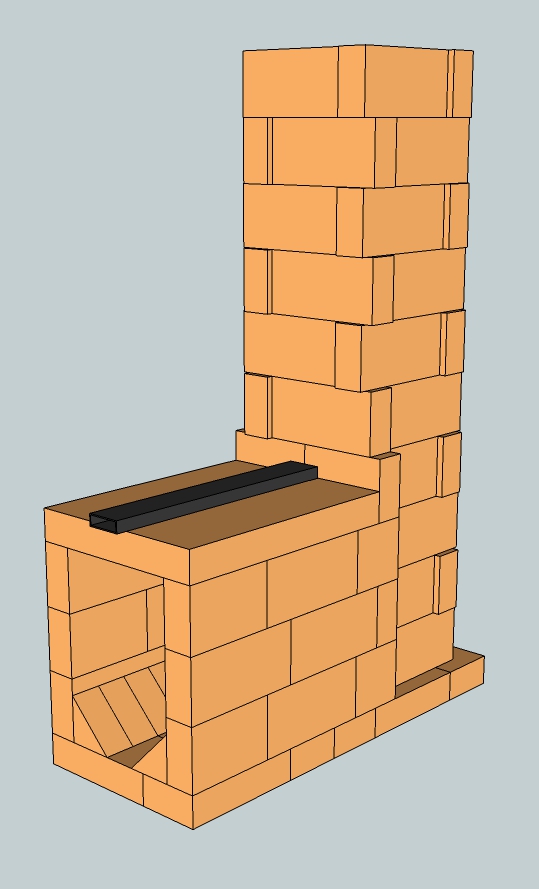

1: Brick core

A masonry firebox and riser is the simplest to produce, although fire bricks need to be cut. By using an optimized design this cutting could be minimal.

(read more)

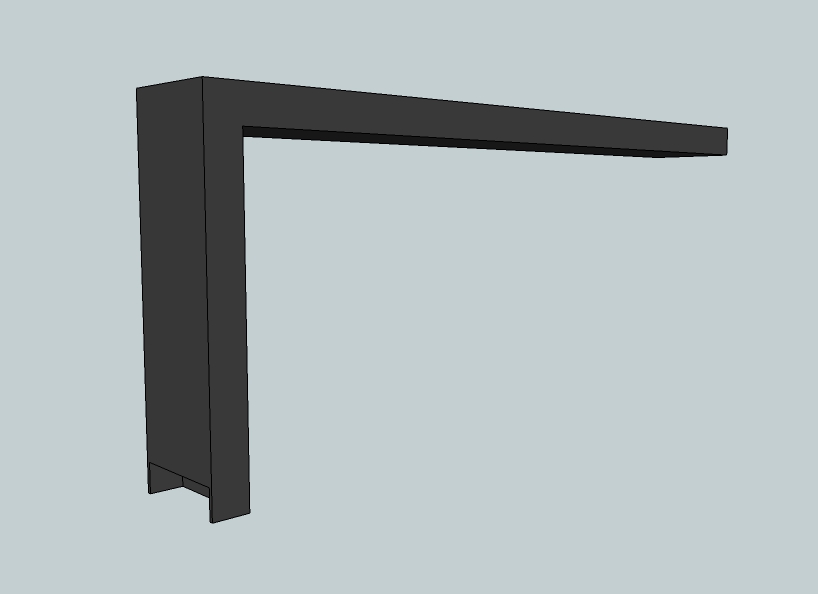

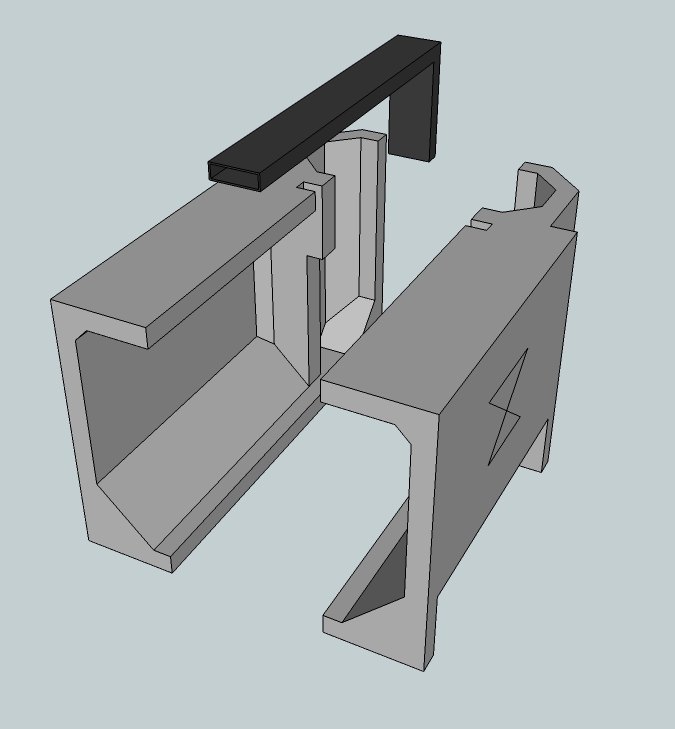

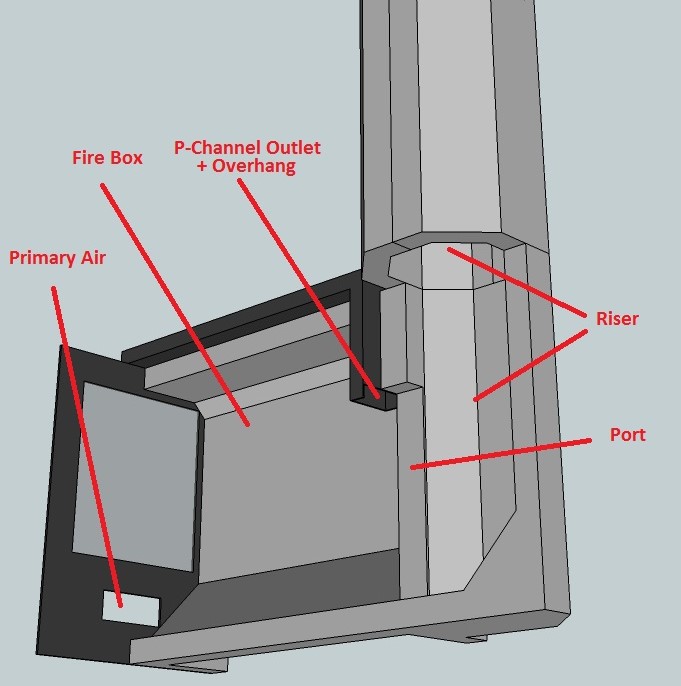

P-channel

This duct supplies the secondary air in the original design. Simply constructed, it works solely due to the law of physics known as the Bernoulli principle.

(read more)

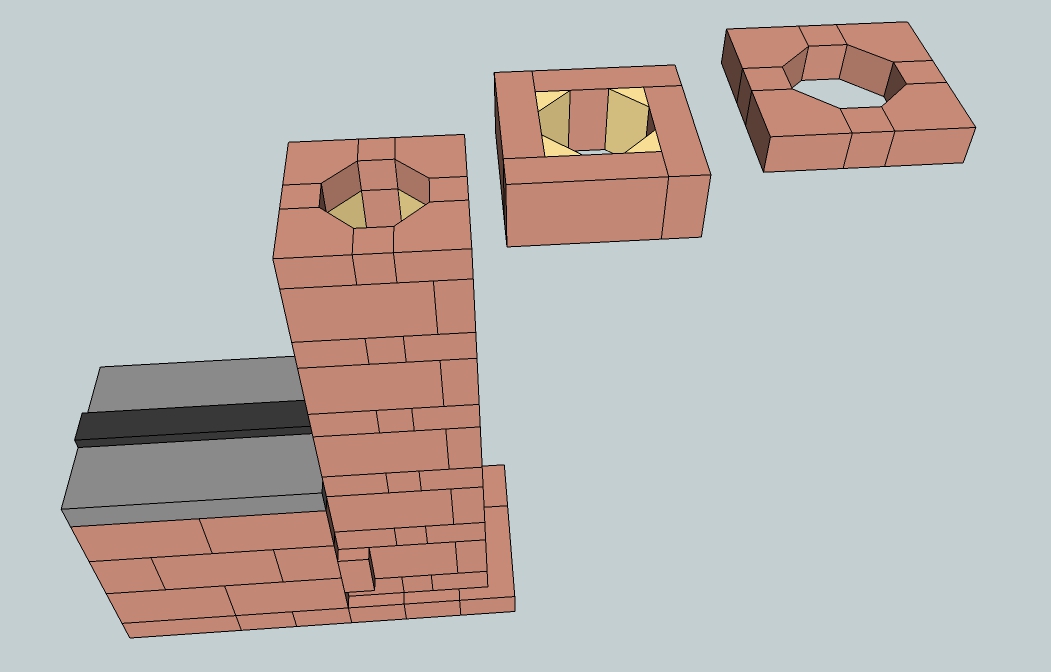

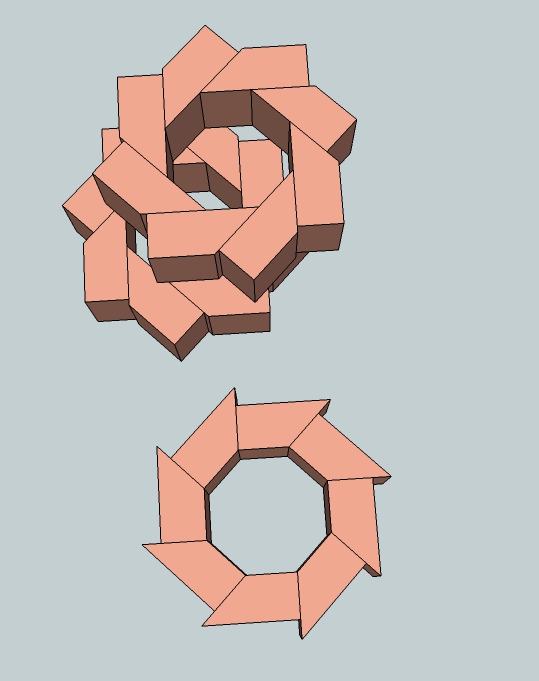

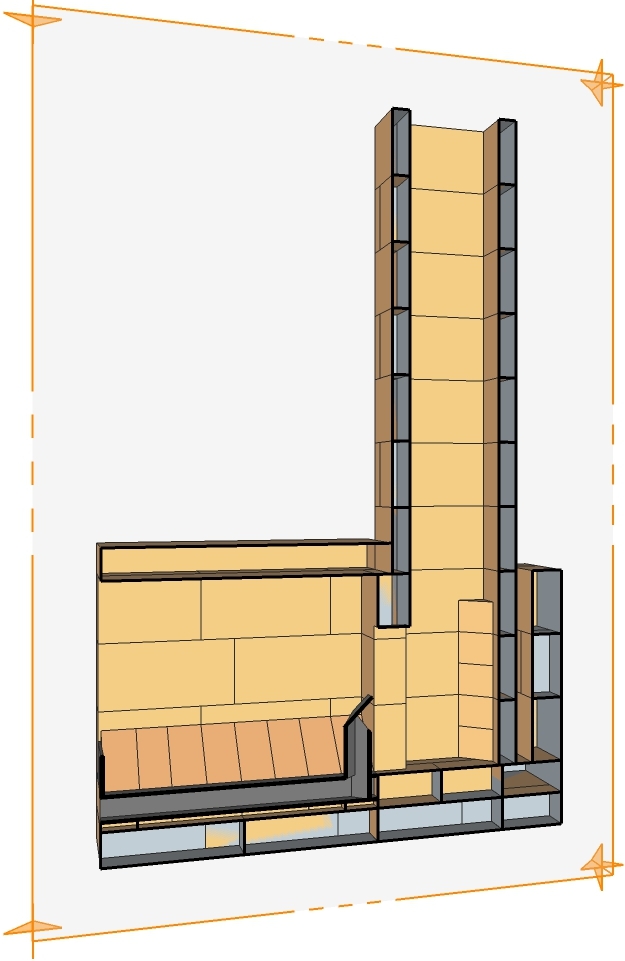

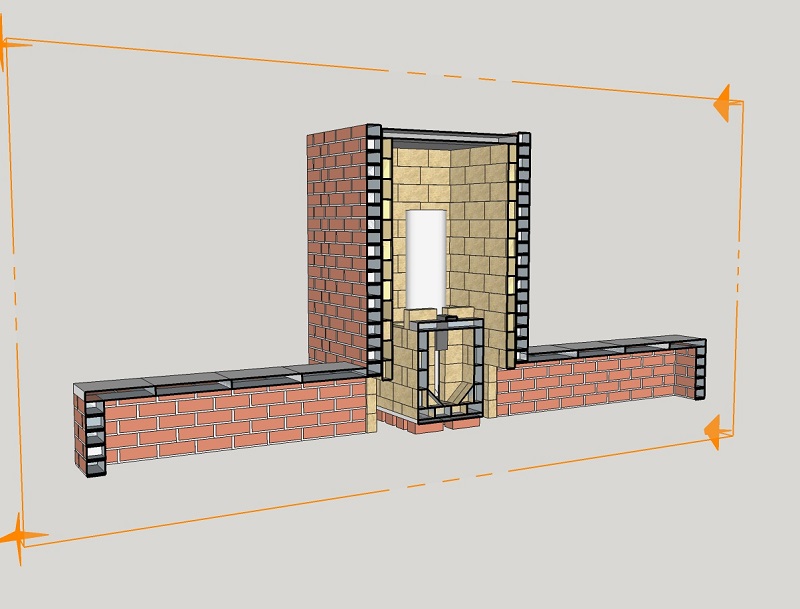

2: Brick core

The problem of the non-round riser of the brick core above is solved in this second design, the riser is now octagonal which is a better approximation to round. The layers are applied alternately on edge and flat in a reasonable running bond.

(read more)

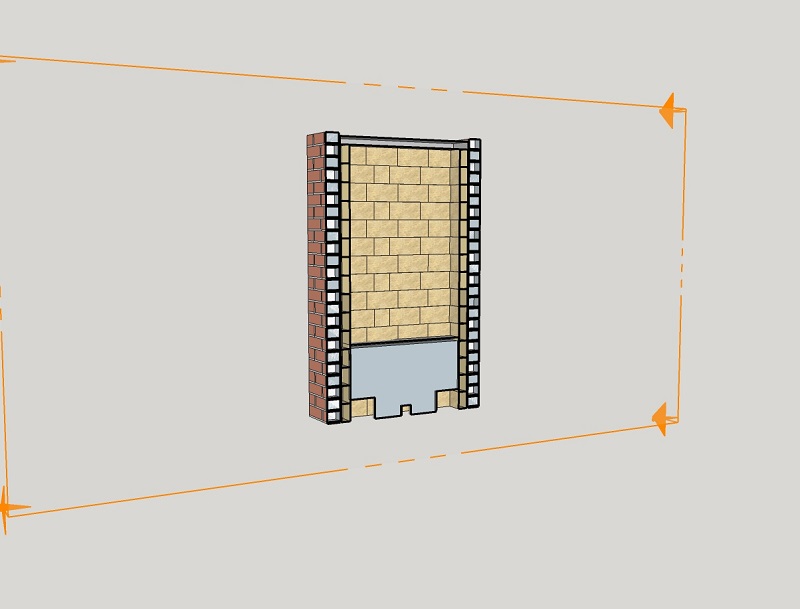

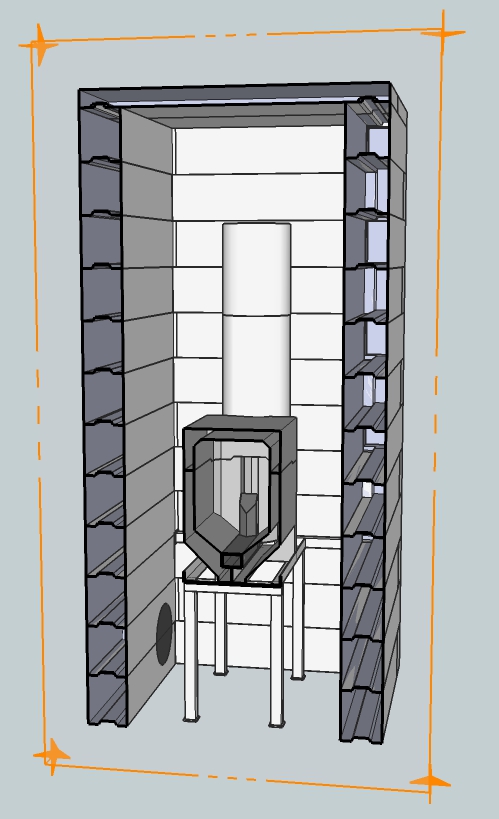

3: Cast core

This is a firebox assembly together with the lower third of the heat riser in two separate parts. This one is built already quite often and works well but is vulnerable to cracking.

(read more)

4: Cast core

This is a recent design (2015) with the firebox divided into three parts. Instead of a p-channel there's a floor channel present.

(read more)

Floor channel

Also a secondary air supply but this one applies the air halfway in the height of the port. This duct lies on the floor of the firebox and recieves its air from the main air inlet.

(read more)

5: Cast core (sidewinder)

A design where the riser isn't situated behind the firebox but at the side instead, allowing a shallower depth.

(read more)

6: Brick sidewinder

A simpler way to build a one-off sidewinder as compared to making molds and cast the parts is building from firebricks. Unfortunately the number of bricks to be cut is quite substantial.

(read more)

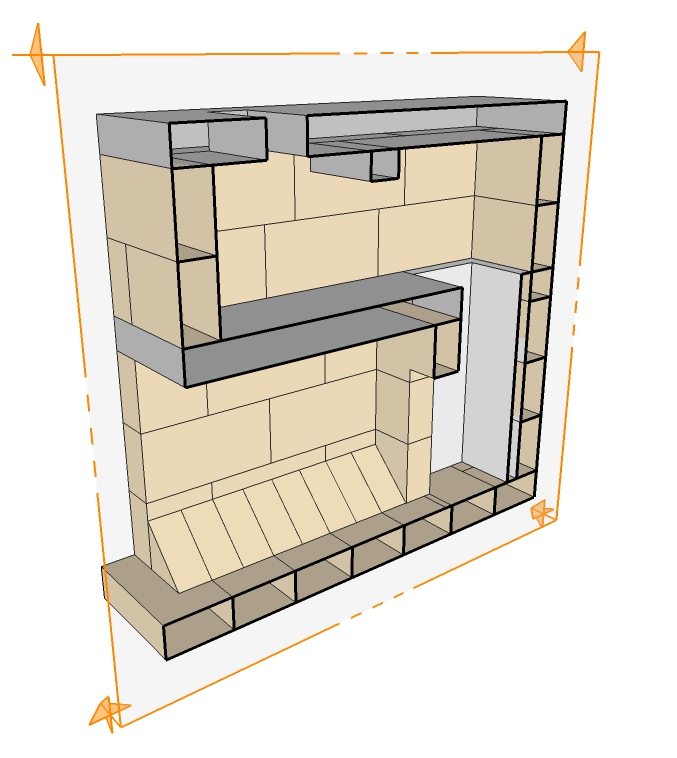

7: A simpler core design

A combination of a square riser and a floor channel. Simpler to build, less cutting of bricks and still very good results.

(read more)

8: Double Shoebox Rocket

Variants that require a considerably smaller installation height. Compact, with a character all of its own.

(read more)

1: Straight brick core

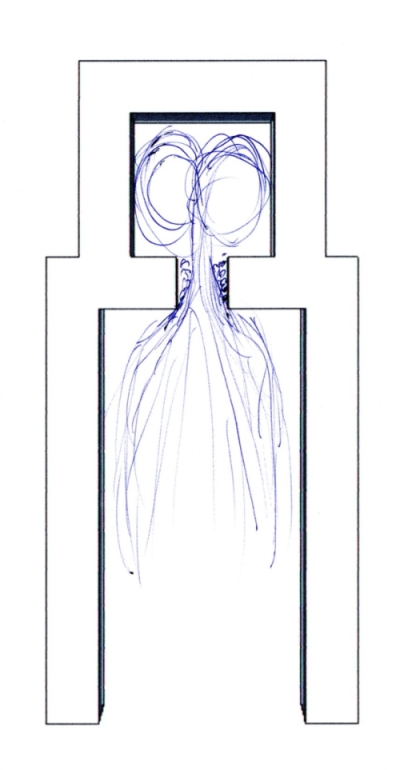

Using a good layout and a suitable clay/sand mix this masonry version is an easy way to test these principles for yourself. This can be done outdoors, in a barn or shed, anywhere that is convenient. A word of warning, the riser will likely have flames shooting out of the top, so use chimney pipe to vent when tested in enclosed spaces. It is not 'only' a convenient test bed, it is more than suitable for permanent use as the core for a space heater (the clay sand mix allows for easy disassembly after testing). As will be described later, space heaters take advantage of the ultra clean burn provided by these combustion units and are able to capture and store the heat produced.

Of course it's sensible to build on stable footing, preferably insulating or using an intermediate insulation layer. The drawing in SketchUp 8 format of this design is available to download via this link. The internal shape of the riser is square, this is not as good as round, it will work but the shape isn't optimal. This version is suitable to build out of hard fire bricks. The layout of these bricks may need adjustment, this design is based on a brick size common in the Netherlands. Naturally, at least the riser should be surrounded by heat resistent insulation material. This isn't the case when this core is built using light weight insulating fire bricks. On the other hand, these are probably just a tad too vulnerable to abrasion to be used in the firebox.

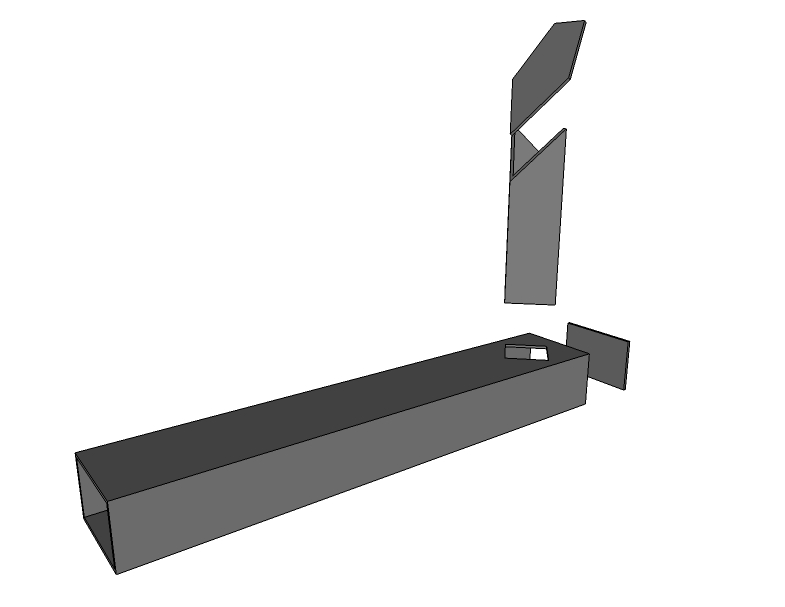

P-channel

The steel rectangular duct on top of the firebox provides the secondary air supply. This part is commonly called the p-channel, short for Peter channel after its designer. Common mild steel or stainless steel is suitable material to manufacture this part. In this 150 mm (6") system a rectangular duct of 60x20x2 mm (2.36"x 0.8 " x 0.08") is being used.

The downward hanging end stops a little lower than the top of the port, providing a small overhang. To keep things simple, this overhang is the same as the depth of the channel. At the back which is facing the riser a small piece is cut out to promote the suction of air. The same principle that causes the p-channel to work, Bernoulli's principle, means the pressure within the system is lower than that outside. Hence no smoke will escape the p-channel, indeed any other small cracks or the main air inlet itself. Conversely, if smoke does come out of the p-channel or main air inlet, then it means there is something wrong in the system.

This secondary air needs to be added to the stream in advance of the strong turbulence in the port and behind. Supplying air in the riser itself seems obvious but it won't work, mixing isn't powerful enough this way.

The duct is being cooled by the incoming air so the life expectancy of common steel is surprisingly long. Damage by corrosion in a space heater which has been used for two seasons is barely visible. So, it would be wise never to shut off the p-channel during operation. It is suspected a larger wall thickness of the duct could promote quicker corrosion because the steel can't shed heat as fast as the thinner material.

2: Straight brick core, octagon riser

The problem of the non round riser is solved in this next design, the riser is octagonal now which is a better approximation to round. The layers are applied alternately on edge and flat in a reasonable running bond. The smoother the riser inside the better, so it's rewarding to be very careful when building this part.

The octagon is a favorable shape because this way the double vortex will initiate earlier in the burn. The drawback of this shape is the higher mass. Such a disadvantage won't be in play when insulating fire bricks are used for this build. Even insulating material around the riser isn't necessary anymore, the bricks are insulating enough by themselves.

The small yellow triangles are in reality the same material, the different color is only there for easy visualisation. Construction of this core is different from the first brick design, the connection between firebox and riser is dissimilar. This drawing is available for download too, use this link.

Below are two other examples of how to make the riser octagonal out of normal brick sizes. Both use bricks that have been cut with a 45 degree angle to create equal sized "halves" to form an octagon shape. The lower one is simple but allows only one size of riser while the other allows the bricks to be adjusted to a slightly wider riser. A wider riser would mean the firebox and port should be wider as well, the scaling method still applies.

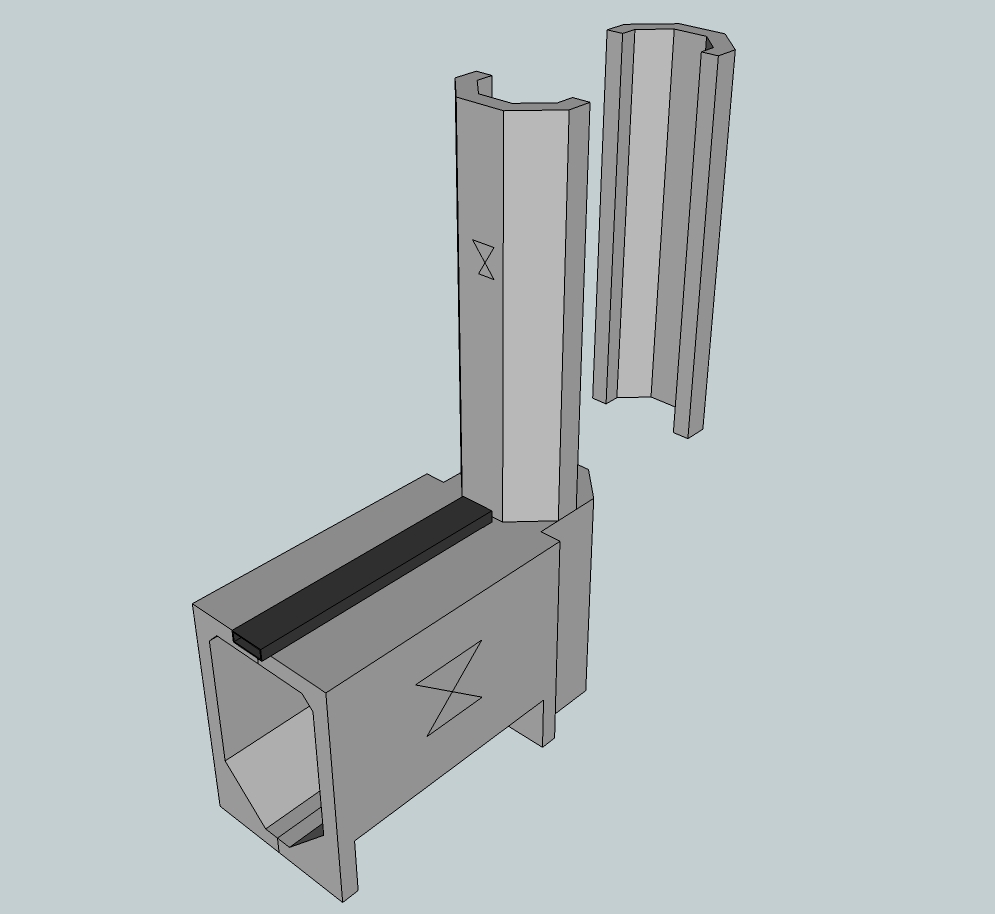

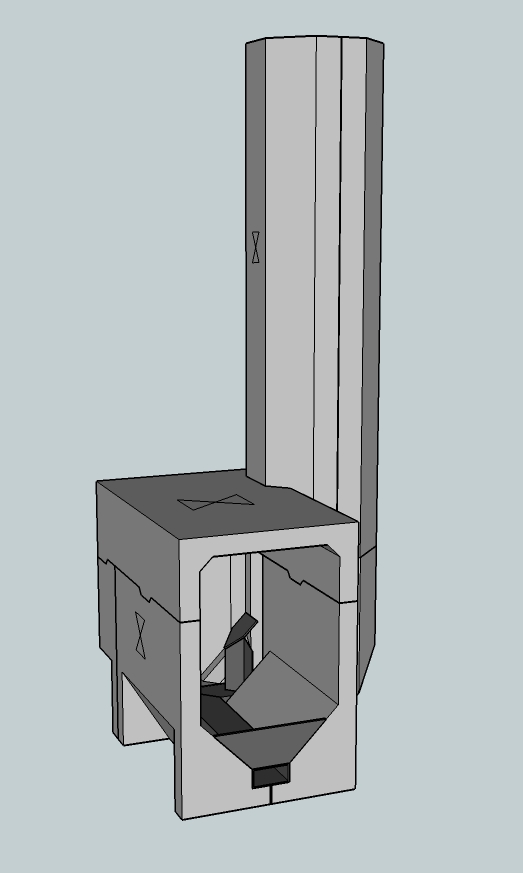

3: Straight cast core, 4 parts

This a tried and proven design with quite a few successful examples around the world. One conspicuous although not fatal flaw is the fact that this version is prone to cracks left and right in the firebox. The firebox will stay whole, after the cracks have appeared nothing much will happen later on. Probably the cracks themselves act as expansion joints, tension is released and the cracks won't grow anymore. Thickness of the walls are as thin as 30 mm (1.18") and where applicable fill pieces are used to economize on material. This isn't done to save money but to reduce the mass of the core. The less material in there, the sooner the thing is up to working temperature.

The part of the riser above the firebox is also split up in two parts which are identical so those could both be cast in the same mold.

The cross on the sides indicates which side is on top during casting. That side will remain relatively rough but that's of no consequence. Not only is the octagon a preferred shape (a very good approximation to round) it is also easily formed when building a mold. A table saw set to 45 degrees will cut all of the pieces required. Careful use of a hand held electric saw with a fence/guide will also serve if a table saw is not available.

This drawing is also free to use, downloadable via this link.

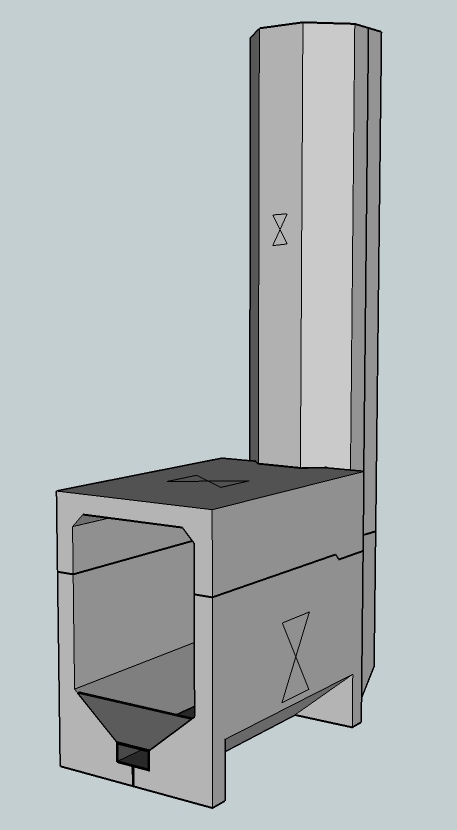

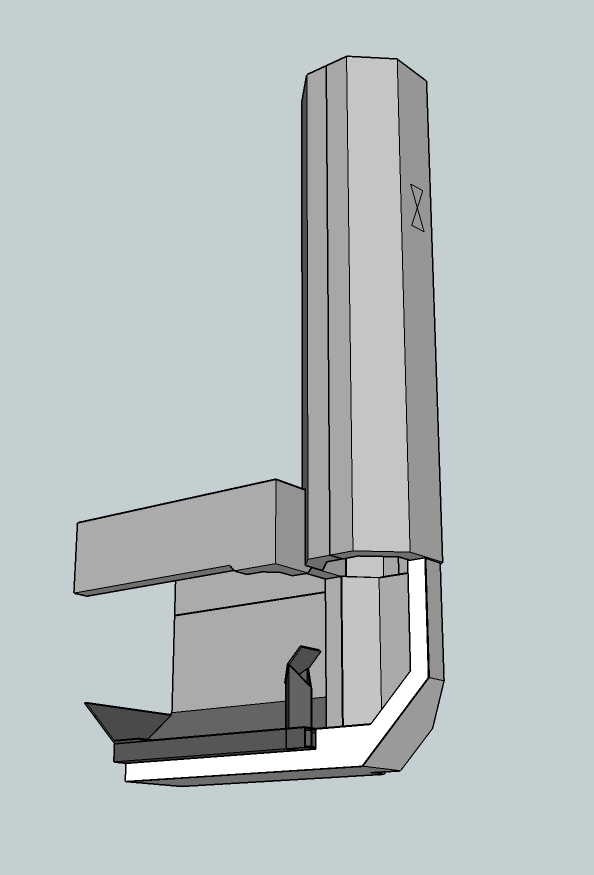

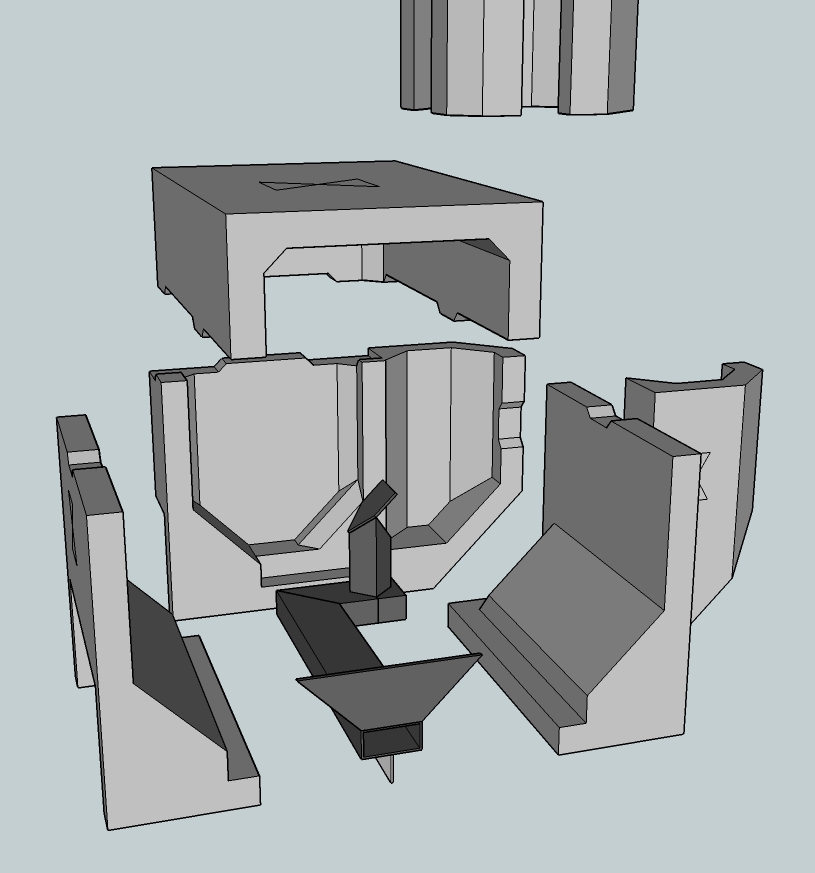

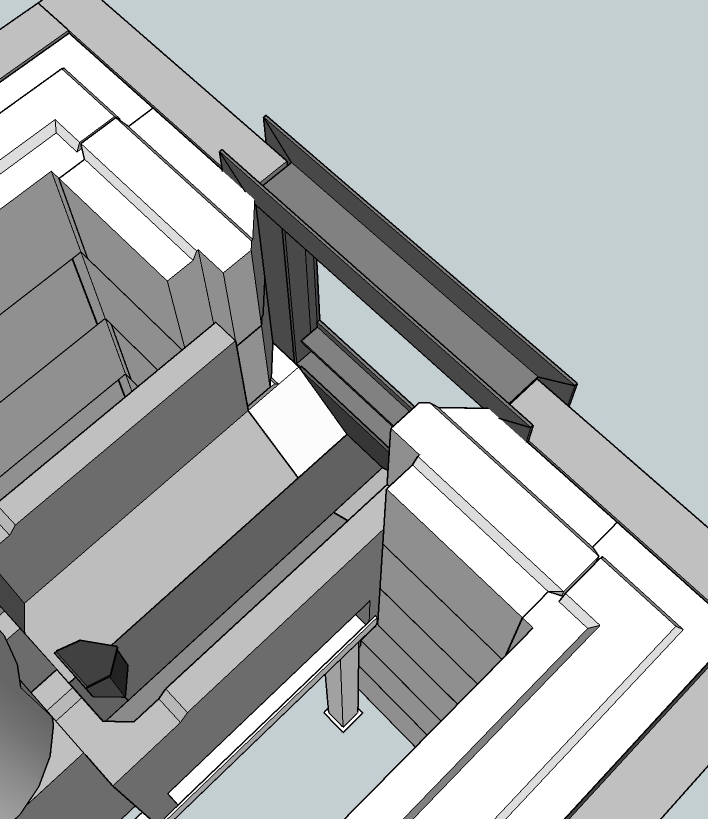

4: Straight cast core, 5 parts

This design is quite recent (2015) and has been in daily use for one winter without visible cracks. In my implementation the bottom rests on a support frame and the upper side is held together by cams and corresponding recesses in the top part. The picture below shows a slightly adapted drawing but is essentially the same as the one in my own heater.

Naturally, the riser of this one need to be insulated from top to bottom as well. Construction is fairly simple, shown by the picture below.

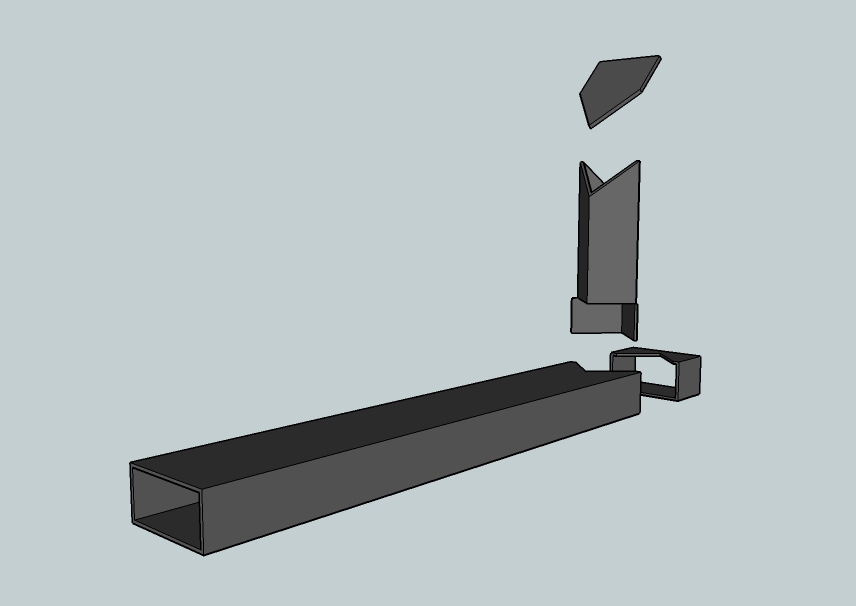

Floor channel

This secondary air supply duct is an alternative to the p-channel, not to be used in the same heater. The construction and placement is quite different, it lies at the floor of the firebox in a trench and it is fed through the same inlet as the main air supply. It is called a floor channel and as such it is a variant of Matt Walker's pre-port tube but the vertical part is shorter, square and less wide. As a consequence, the tube is less of an obstruction inside the firebox.

On top of that the air is supplied halfway up the port which in turn keeps the double vortex low in the riser on average. This version is somewhat easier to produce than Matt's, the only tools used to produce this thing is a small grinder equipped with a cutting wheel and a welder. This floor channel is very easy to replace, an advantage as compared to the p-channel which can't be taken out unless the heater is opened up.

The channel is made out of normal 2 mm thick steel rectangular duct and has very little corrosion or deterioration after a year of daily use in a temperate marine winter. The explanation for the lack of corrosion is that the inside of the duct is cooled by the incoming air. And the duct itself is in an oxygen poor corner of the firebox while the burn is going on, steel won't corrode in the absence of oxygen.

So, this is one of the few steel parts inside the firebox which isn't destroyed in ten runs, durability is reasonable. My next channel will be made out of stainless steel 304, life time expectancy should be even better.

The burns during winter of 2015/2016 were entirely dedicated to get this air supply right, about 12 variants have been tested. The drawing shows a horizontal duct of 60x30x2 mm (2.36" x 1.18" x 0.08") , the vertical piece measures 35x35x2 mm (1.38"x 1.38" x 0.08"). The internal cross section area of the larger duct is about 1.5 times as large as the smaller one. This is not a coincidence, three sizes of the horizontal pipe are tested in several combinations with three vertical sizes. The duct of 60x30x2 is just as effective as a 60x40x2 item, as long as the inlet is larger than the exhaust of the channel. Using the steel ducts as drawn, the vertical part is 5.4% of the riser CSA and the horizontal part 8.25%. By keeping close to these percentages it is possible to calculate the dimensions for a larger or smaller batchrocket according to their larger or smaller riser CSA.

01/05/2019 A somewhat simpler construction together with a larger feed part and a higher stub, according to the latest findings. The air flow is optimized in such a way that the top half of the port recieves the majority of the secondary air stream.

The feed is close to twice as large as the stub, csa-wise. It's also produced using a grinder with a thin cutting blade and a welder. A drawing of a size which is suitable for a 150 mm (6") system can be obtained here.

In contrast with the normal implementation this core version should be lit on top of the fuel pile at the back, known as "upside down firing". This method will deliver the best results.

This diagram represents a testrun using larger pieces of bone dry birch, lit on top. The start temperature of the heater itself happened to be moderately warm, start temperature in the chimney 30 ºC (86 ºF). The CO dropped at 18 minutes into the burn below 500 ppm and stayed down there for 58 minutes. The averages of this run: O2 13%, eff. 95.2%, CO 282 ppm, Tr 66.4 ºC (152 ºF). Mark the end level of CO is unusually low.

To conclude: the drawing of this core is available via this link.

5: Cast sidewinder, 7 parts

This is a variant of a batch box rocket where the riser is placed either left or right of the firebox. The design is developed by Adiel Shnior and Shilo Kinarty, two guys building rocket mass heaters in Israël. Max Edleson, a heater builder in the USA named it the "sidewinder". This is the name of a desert snake which moves by winding sideways over the sand.

As the riser is no longer directly in line with the combustion chamber, it is naturally no longer symmetrical. As a consequence, we need an extra mold to cast the combustion chamber, see below.

This design is similar to the earlier with a separate top piece, the most complicated mold is the back wall which has half of the lower part of the riser incorporated. It is possible to get away without making a second dedicated mold to cast the combustion chamber sides if a "fill piece" can be placed and secured into the mold prior to casting at the spot where the port should be. In this manner the one mold can cast both sides, one with an exit to the port due to the fill piece put into place before casting, the other without an exit. The top part of the firebox is the same as in the straight design and the other lower half of the riser is a relatively simple mold. For better understanding of the layout there's an exploded view below.

It looks very complicated, but with some careful inspection and thought it is entirely within a competent home handyman's ability. Although seemingly more complicated, these molds are assembled no differently than described in the "How to build" section. A coated plywood box with suitably formed pieces of extruded polystyrene (or other) to form the final shape.

To many this might be the first attempt to think with 'negative spaces' and how to demold the casting. I do believe it is within the capabilities of a good 'backyard tinkerer' so fear not. It might be a very good idea to test your molds with much cheaper materials, such as plaster of Paris, or even a weak cement sand mix, before (potentially) wasting the very expensive refractory castables on a mold that might need modification before the proper end result can be obtained.

As mentioned in the introduction, this is an open source project hence is available for commercial purposes (please read any attached conditions to that in the introduction section). If it is planned to make more than a few of these it is sensible to first make positive 'master molds' (that is, the actual shape itself, the 'positive') and from them make the rubber molds (ie these are now the 'negatives') to be used for the actual production run.

These second molds will need to be replaced periodically by recasting from the master mold. It seems to me a viable business opportunity to make and sell these castings along with good instructions on assembly and also the 'DIY actions' required to reach the final product. The total number of molds including the heat riser is five, possible to cast 7 parts in there. The drawing of this design is available through this link.

6: Brick sidewinder core

This design isn't difficult to build using fire bricks and a wet saw. Not more difficult than the straight batch rocket design, anyway. In order to make things a bit simpler the design size is a little bit enlarged, from 150 mm (6") to 160 mm (6.3"). By doing this, the firebox becomes also slightly larger so somewhat larger and thicker fuel could be loaded.

It would be sensible to keep the same depth as in the straight brick core version. Together with the riser no longer being at the back this would result in an installation depth of 486 mm using bricks this size. This would be a saving of 216 mm as compared to 702 mm of the straight core. The differences in firing behaviour are fairly small so this will be a good alternative. These sizes are all nominal, no thickness of the mortar between the bricks is taken into account.

The floor channel's vertical part is somewhat lengthened to accomodate the larger size of the riser and the port. Besides, this channel is constructed simpler as compared to the one in the casted sidewinder version, no 90 degree bend in it and the vertical part is placed a-symmetrical on the horizontal part in order to create sufficient distance to the port. On both sides of the vertical part there should be the same space as half the port width, measured perpendicular to the sides of the vertical channel, between this and the corners of the port.

Of course it is possible and also better to use the octagonal riser of the design 2:Brick core which will yield better firing results. Use this link to download the SketchUp drawing.

7: Another core layout

Between autumn of 2017 and the summer of 2018 quite a bit of experience has been gained with a layout consisting of a floor channel and a riser that is square instead of the more usual round or octagonal shape. It's performance is at least as good as a batchrocket with p-channel and round riser but has the accompanying advantage of a much easier construction - less cutting of bricks and a simpler layout, building should be easier. At times during this testing the back sweep, the ramp at the bottom rear of the riser, was left out (giving further simplicity) with equally excellent and encouraging results. (see under video for diagram)

In this layout, it is now only at the back of the riser below the level of the port that we have chamfered corners (watch for this in the video) resulting in a half-octagon that allows the double vortex (rams horns) to develop more easily.

The already published dimension tables are to be used with this design. That is to say a 150 mm design has a square riser 150mm*150mm and all of the remaining dimensions come from the spreadsheets and tables for a round 150 mm riser. Similarly for all other system sizes, so a batch rocket of size (X) has all of the dimensions for that system size (X) from the tables coupled with a square riser of that dimension (X*X). The round cross section riser is simply replaced with a square section riser with the side of the same dimension as the diameter of a round one. Please read about the consequences of a square riser as opposed to a round one in the "Building" chapter.

This design came about rather by accident, during a workshop on the Spanish island of Mallorca in November of 2017. The wet saw that had been hired was not capable of doing the 45 degree cuts to the accuracy we required, forcing me to try this method of construction. It was not as much of a stab in the dark as might be implied, my experience over the years had led me to suspect this method was entirely workable, and some separate experiments had strongly supported that suspicion. Perhaps a lucky set of circumstances. And it worked flawlessly straight out of the box so to speak, wet bricks and all. Here is a time lapse video of the entire build. Drawing of the build can be downloaded via this link.

Much of the further actual building and testing of the concept was done by Yasin Gach of France during other workshops and commercial builds. Recommended layout for this floor channel/riser combination is now like the drawing and picture. The drawing of the core can be downloaded here.

8: Double Shoebox Rocket: DSR 1, 2 and 3

Autumn 2021.

All previous designs are variants of the vertical riser, whether behind or beside the fire chamber. One disadvantage of this is the considerable installation height. A vertical riser, together with its minimal top gap, sets a fixed height for any method of extracting heat from the flue gases, which can be cumbersome in some applications. In the course of 2017 I began experimenting with a riser that lays horizontally on top of the fire chamber. The advantage is a lower installation height and because there is no riser behind it, the depth is approximately the same as with the sidewinder. The shape of the whole is reminiscent of two boxes on top of each other: the working title therefore became "double shoebox rocket". It never happened to come up with a better name so it stayed that way. This soon became an abbreviation: DSR, and Satamax Antone from France thought that could be an abbreviation of Désirée. Very romantic, because that name means "the long-awaited one".

At the moment there are three variants of the same concept.

Development of the first (DSR1) stopped in 2018, because it never led to a reliable design. As a free-standing structure with a meter of pipe on it, the DSR1 did well, very well in fact. But built into a few barrels and connected to a full chimney, it tended to burn harder and harder until all the fuel was used up. Not a big deal in itself, but during such a thermal overdrive large dark gray smoke billows came out of the chimney. With the current focus on reducing particulate matter and smoke nuisance, this is not something that would be appreciated by the neighbors.

Much of the DSR1 experimentation has been published on three forums: Ecologieforum, Donkey32 proboards and two links for the third forum Permies.com and Permies.com DSR cookstove.

All this is relevant to the development of the DSR3. That is why I have told the story here.

In the fall of 2018, development continued with the second variant: DSR2. This has resulted in a useful core. Many of the good qualities of the original batch rocket can be found in it.

This development has also been published as usual: Ecologieforum and Donkey.proboards.

In short, this DSR2 core consists of a fire chamber with a short riser behind it, this is the first box. The proportions of this box are the same as those of the straight batch rocket, so the dimensions are in accordance with the well-known table and spreadsheet. On top of the first is a second box, the same width as the firebox below and with a height equal to the width. The total depth of both boxes is also the same, so all walls can be placed on top of those of the bottom box. A door can also be made in the top box, so that it can function as a (black) oven. The fire chamber has a normal port of the same size as in other batch rocket designs. The short square riser opens into the top box, which has a final exit in the form of a transverse slot relatively close to the front. Also in the top box, halfway along its length, a so-called “stumbling block” is dropped transversely beneath the ceiling.

With a short chimney on top of the exit, this version works perfectly. However, an open version is not suitable for indoor use; a door in front with an air inlet is much safer. So far (autumn 2021) quite a bit of experience has been gained with this core. In the meantime, some principle drawings have also been made that show a few possibilities. One of them has a fully developed door and air inlet combination. All files have the SketchUp version 8 file format and can be downloaded here.

DSR2 closed, the cast version with door set and combined primary/secondary air inlet.

DSR2 open brick, the brick version, as shown above.

DSR2 open split, a version built of thin chamotte bricks with a box of ceramic fiberboard around it as a structural element.

DSR2 cast open, the cast version without door or secondary air inlet.

The version with secondary air inlet, here in the form of a floor channel, deviates somewhat from the other principle cross-sections. The fire chamber is slightly higher, to compensate for the thickness of the floor channel. Accordingly, the gate is also higher. All other sizes are the same.

There are two builds of a DSR2 core with a heated bench that I have worked on. The first is in Amayuelas, in the north of Spain. The exhaust is located low in the small bench on the left. The drawing can be downloaded via this link.

The second is in Gierle, south of Turnhout in Belgium. No exhaust is shown in this one either, it is placed low in the back wall of the right-hand bench, close to the bell. Download via this link.

Work in progress, more to come!

Preface

In this chapter will be shown what is actually done to create a complete space heater using the combustion cores introduced previously. The concepts will be explained as we go, but not all of these will necessarily have accompanying photographs if copyright restrictions are in place. But measurements and sketches could be converted to 3D drawings in SketchUp format, by the builder of the heater or by me in due time. This way, sufficient information will be available to people who like to build one or more of the designs for their own purposes.

The true magic of this technology is realised once we couple the clean burn technology of the combustion unit/s covered previously with effective ways of harvesting that very clean, smokeless heat. This can be done in a number of different ways that allow us to have different applications. We can build a space heater for applications that require 'heat on demand', for example a workshop that is only occupied during working hours. This type has very little mass but very high radiant output. For other cases (eg in a house) where long term 'constant heating' is needed we use much more mass that provides a lot of heat storage. These different approaches will be covered in this section.

All described variants are designed and/or built by Peter van den Berg, unless stated otherwise.

Only open source designs and descriptions will be included on this site, whether for people's private use or commercially. The Creative Commons license Attribution and ShareAlike is allowed, the GPLv3 public license is also possible as an alternative, one-way compatible with the CC license mentioned here.

Workshop heater

Consisting of three oil barrels and a cast batch box rocket core. The core itself weighs 60 kg (132 lbs) but as the three steel oil barrels have very little mass there is little delay to the heat output of the core, basically instant heat.

(read more)

Bell with two benches

This was built during a workshop so not as a permanent construction by a complete team in a little more than 3 days. A very interesting build, it showed outstanding performance.

(read more)

Bell heater, cast construction

A 2015 design and build of a heater which is entirely dry stacked out of cast parts.

(read more)

Central heating boiler

Also a design from 2015, the whole of it is made of a lot of stainless steel, fire brick boards and split fire bricks. It burns clean and hot, the unpressurized storage is heated up with it and in turn the in-floor heating is fed with warm water.

(read more)

Pizza oven / pool heater

A third 2015 design, a batch rocket driving a pizza oven, warming the terrace and heating the swimming pool. Not for the fainthearted, but a very rewarding build for Tom De Smedt.

(read more)

Open batch rocket systems

These systems are built and run without a door or secondary air intake.

(read more)

Three barrel batch rocket

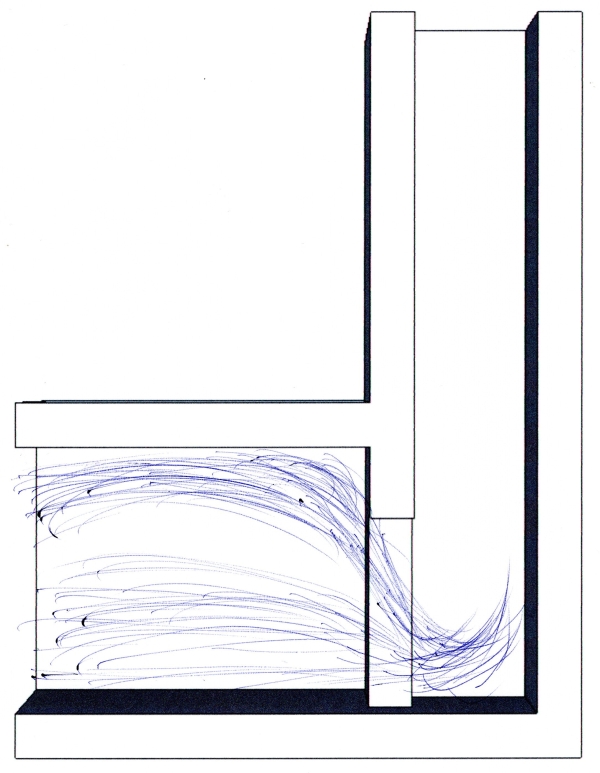

During winter of 2013/2014 this heater functioned as the focal point of my old workshop. It is built as a 150 mm (6") riser diameter system, the same size as the chimney pipe. The whole of the heat extractor side consists of three barrels on top of each other, forming together a single cylinder. The top and bottom lid of the middle barrel are both cut out. The lower barrel is open at the top and the top one is open at the bottom. Leave about 25 mm (1") around the perimeter when cutting out the lids, the added strength keeps the barrels circular. The batch rocket combustion core is a cast item which is protruding out of the side of the barrel cylinder. See the diagram below.

The masonry column in the lower barrel is resting directly on the floor, it doesn't rest on the bottom of the barrel. A square opening in the bottom cut for the size of the column allows that to happen. A flange is bent and hammered on all four sides of the opening, leaving a gap between the brick and steel which is stuffed with superwool to seal it off. This way, both the barrel and the column rest on the floor independently. Another opening is cut out and flanged to allow the core to stick out.

The core doesn't rest directly on the bottom flange, the internal masonry column and the external masonry support (see diagram just above) are sized so that the cast core is elevated about 8 mm (0.315") above the flange. A strip of superwool is glued (heat resistant stove caulk) to the flange which provides the seal. The riser isn't located exactly in the middle of the barrel so the firebox isn't protruding out as much.

The gaps between the side of the firebox and the flanges are stuffed with superwool as well, as is clearly visible. There's another cut out in the second barrel plus a small one to give room for the p-channel. Flanges are bent/hammered all around and the gaps filled with the same sealant.

Next step is the placement of the riser, I don't have a picture of this, regrettably. A vacuum formed superwool duct, common in the metallurgic industry, is used as the riser in this heater. In the industry this type of duct is used to pour molten metal through to fill molds. Google "riser sleeve" or use this link.

The final step is preparing and placing of the third barrel. The rims are sealed with aluminum tape, this won't last forever but it is in full view so it's visible and easy to replace once it is worn out. The gas flow internally does not hit the rims of the barrel as such, the one inch around the rim that was left when the top and/or bottom of the barrels were removed causes the hot gas to bend around them and so the rims where the aluminium tape is used to seal the barrels always remain several tens of degrees cooler than the rest of the barrel.

The piping hot gases are spewn upward in the cylinder and need to go down to get to the only exhaust opening close to the floor. This exhaust is situated even lower than the firebox itself, which is around 500 mm (1'8"). As such, this barrel tower is acting like a bell heat exchanger as described in the "Bell theory" article. In addition to it acting like a larger bell due to the height of the combustion core, it makes for very easy and less streneous feeding of the fire than having to bend down and kneel to put the wood in.

To prevent having a restriction for the gases to access the exhaust opening (a common mistake and one of the first points to check in a poorly performing heater) the pipe is mounted about 100 mm (4") from the floor. Making a larger hole of 200 mm (8") is another way to help avoid any restrictions. In combination with a 200 to 150 mm (8" to 6") reducer to the diameter of the chimney pipe.

During the top of the burn the temperature of the uppermost barrel can easily reach 200 ºC (392 ºF) in this situation. So it would be sensible to keep combustible materials well away from the heater. Indeed when constructed in this manner treat it as a "normal combustion heater" and apply any and all codes applicable to the installation of such metal boxes.

I did not ever get around to making a door for this variant, a separate sheet of Robax heat resistant glass is used instead plus a couple of firebricks to shape the air inlet. Of course a door can be made if so desired. The chimney stack is straight, uninsulated masonry and 8.5 m (27.9') high, measured from the point where the pipe is inserted through the brickwork. Here is a low quality video showing in steps the burn's progress.

And last but not least: the report on the Rocket Stoves Forum dating from October 2013 about this subject.

No 3D drawing avaiable, sorry.

Bell with dead-end benches

This mass heater was built during the 2015 Annual Meeting of members and interested parties of the Masonry Heater Association of North America. This organisation of heater masons invests a lot of effort in making clear to governmental parties that their heaters are among the cleanest in the United States and Canada. Other activities are educating the members and providing standard designs, so in that respect they embrace the open source ideal shared by this website.

The main bell is drawn as a double skin design but during the (6!) workshops plus several mini-clinics and demonstration projects it turned out that the fire bricks were in short supply. In response to that problem the layout was altered to a complete single skin build, only the top half of the main bell was built out of fire brick in order to cope with the expected high temperatures. In North America, normally the masonry heaters are built as double skin, the inner skin entirely out of fire bricks. We skipped that layout during this workshop, the goal was to demonstrate a proof of concept for the MHA members, a bell heat extractor married to a batch box rocket core. It turned out to be quite a success, the thing burned really clean and the benches heated up without a hiccup, right out of the box so to speak.

A vacuum formed superwool cylinder of 200 mm (8") diameter was used for a riser, the benches are drawn as single skin and the main bell double skin. A number of the MHA members found it strange the benches were built as dead ends in opposite directions. Doing it this way, it would be impossible for the exhaust gases to stream through in one, let alone both of them. The next picture shows the heater during the curing stage, the steam is coming off as lazy clouds. The top of the pictured bench already shows lighter spots. The end of the bench is still wet being completed last, less than an hour before lighting first fire.

There are a few tricks in this construction in order to get the hot gases to enter the benches, stream along the top of the benches and cool, and make their way back to the main bell to the exit located at the bottom. This mechanism relies on a principle of physics, the fact that hot gases are lighter because they have expanded. This is called the buoyancy of gases, driven by gravity and is the way a bell system works. Hot gases tend to rise and colder gases descend, to the exit. See also Bell Theory.

From this cut-away it can be seen that the opening between the main bell and the benches have no obstructions, the interior of the bench is carried through straight into the bell itself. In fact, this means that the benches are actually simply a continuation of the bell and form a single, larger bell with heat distribution sculpted to satisfy a new set of demands. Another illustration of the versatility of the bell concept. As covered in the Bell theory section, we can see that as the gases enter from the bell into the benches they enter a *much larger volume* and so slow down greatly, rise to the top, shed heat and make their way to the exit.

So there's a lot more time to transfer its heat. Naturally the main bell is the first to receive the gases, indeed the hottest gases, and so is the first to heat up. They then cool and make their way to the benches. So it is to be expected that the bench warms up after the bell, and in this construction that time delay was just 20 minutes. If the bell had been made of a double skin of bricks according to the drawing, then the benches would have been the first to warm.

The placement of the exhaust opening to the chimney stack is very important in this design, as in any bell design. As this design has benches attached to it (absent from the previous examples shown) thought needs to be given to how we get the hot gases into the benches and not 'short circuit to the exit flue' beforehand. The drawing below shows how it was achieved. A fireproof baffle board (in this case calcium silicate) is placed off the rear wall of the main bell and capped off at the top, see 3D drawing how this is done. Not seen in the picture below is the exit flue, 'hidden' behind the baffle plate. The circumference of this baffle board multiplied by the distance between it and the rear wall of the bell should be much larger than the cross sectional area of the flue. This is to ensure we do not have a restriction to the easy flow of gases into the flue. The openings cut into the baffle (as seen below) are also of a size much larger in area than the cross section of the flue. Again, we do not want restrictions to the gases. There is no 'opening' at the top of the baffle board, we do not want access to the exit flue until after they have opened into the benches. Note that the cutouts in the baffle are well below the level of the benches.

This baffle plate has helped us to achieve all we want from a bell. As the gases can ONLY reach the exit flue by entering behind the baffle plate from the bottom, only the coldest gases escape. To reach that opening the gases must have had to enter the benches and cool. We can also now see how "dead end benches" that initially baffled some of the attendees are so effective. It should also be clear that a baffle board is not the only solution, it happened to be the quickest and easiest way to do it during a "time starved" week. All that is needed is that the gases reach and warm the benches before exiting the flue, so it could be done with a shallow and wide opening at the bottom of the rear wall of the bell which leads to the vertical stack by means of a funnel shaped brickwork.

Large North American masonry heaters usually have a "bypass valve" incorporated. This is a steel or cast iron plate which is mounted in such a place in the heater that when it is opened by turning or sliding out, the hot exhaust gases are allowed to enter the chimney directly by a shortcut. This is a way to heat up the chimney stack before the masonry mass is warmed up so the chimney draw is initiated beforehand. Its main drawback is it complicates the construction and introduces a weak part in the heater which shouldn't be there in my opinion.

Still, it can be very handy when a cold heater needs to be lit in the depth of winter in an icy cold house. When one thinks such a bypass is desirable in this design, such a valve could be mounted in the area of the baffle board. Preferably not at the top of the bell which is the hottest area where a steel bypass valve could become warped or destroyed in time. The bypass valve shouldn't be confused with a 100% closing flue damper which can be very dangerous when there are still some glowing coals under the ash. Carbon monoxide can't be seen or smelled and it will kill people in their sleep when leaked into the house. A 100% closing door is a much better alternative and in addition to that, a CO detector is actually an indispensable safety measure.

The MHA meeting was a memorable event, with a couple of prominent names participating in the Rocket Heater team. Lasse Holmes, the creator of the batch rocket idea, Leslie Jackson, co-author of the "Rocket Mass Heaters" book and Kirk "Donkey" Mobert, creator of the first dedicated Rocket Mass Heater Forum. The photo below shows Lasse and Leslie dancing in front of the heater (or around the fire?). Just as an aside, the batch rocket heater here produces less smoke than can be seen in the picture.

The two action pictures are copyright MHA, for more pictures commented by MHA's Norbert Senf and myself see the photo report of the MHA of this workshop. The 3D drawing of the complete heater is available through this link.

Bell heater entirely of cast parts

This is a batch rocket variant designed and built in 2015, consisting entirely of cast refractory parts. In such a project the financial investment in molds is very high. So much thought was put into devising a way to use as few unique parts as possible, thereby cutting down on the number of unique molds. As can be seen there are just a few parts repeated many times, the same few molds being used over and over as required. The finished external dimensions of the heater are 98 x 98 x 210 cm (3.22" x 3.22" x 82.7"), and all up it weighs in at a little more than 2000 kg (2.2 US tons).

The outer finished face is made of specially ordered castable refractory in a terracotta colour, and consists of 28 identical parts which interlock with each other (for those counting in the picture- a good way to conceptually grasp it, the last seven pieces form the rear wall behind, in other words four walls of seven pieces each). The interlocking dovetails are seen at the corners, showing how the use of the same shape placed 'up and down' alternately manage to interlock with each other.

An added benefit of interlocking shapes like this is that it makes the construction easier as each piece is an easily handled and assembled part. A close look at the dovetails in the picture shows the slight, but important, angle they are cast at. This ensures that they lock together tightly, indeed force the dovetails to close. Not seen are "ball and dimple" locating pins that locate and secure each layer to the other layer. Knowing that, and referring to the picture it is clear that each layer is locked together as a unit by the wedge action of the dovetails, and each separate layer is locked to the next by the "ball and dimple" pins. All this allows gravity to do the job of holding it all together, they are not glued, mortared or fastened in any way. For full and complete details see the SketchUp drawing of this project, there's a link provided at the end of this article.

The door is made of steel T-profiles and hinges in a frame made of steel U-profiles with the open side facing outwards all around. That allows the outer skin pieces to fit into the open U which then supports and locks the door frame into place. (This can be seen more clearly in another photo below.) A simple tilting valve without hinges is mounted in the door which provides for the primary as well as the secondary air supply.

The firebox is identical to the description of "4: Cast core" in the chapter "Designs" and consists of 3 separate and different parts. The bottom left and right parts together form the port and base of the riser and the third part completes the combustion chamber when placed on the bottom pair. See assembled construction picture later. The top part locks into the locating lugs seen below.

The core rests on a welded steel frame incorporating adjustable bolts in three directions to obtain correct and secure placement inside the bell. This frame is also holding the left and right halves together by force of gravity (again). Both halves are supported by the frame's left and right outer ridges but not in the middle. As a consequence, both parts have the tendency to fall in each others' direction so the vertical seam will be held closed at all times. Note the steel frame doesn't support the core all of the way to the front, a small section of the core in unsupported by this frame. This will be explained later.

The upper part of the riser consists of a vacuum formed superwool circular tube which rests freely on the core base only held in place by a couple of short centering pins. Done in the most simple way: a couple of small holes drilled in the refractory and a couple of shortened nails inserted.

The internal wall of the bell is built out of two different blocks, repeated 24 times each (naturally a slight modification to the exact duplication of these two parts occurs where the exit flue and firebox appear, other than that they are, like the outer skin, a simple repetition of parts). Note the tongue and groove seen in the picture, and careful inspection will show the tongue and groove exists at the ends of the pieces as well.

One row consists of 4 parts and is 150 mm (5.9") high and 120 mm (4.7") thick. Every row is turned a quarter horizontally relative to the previous one, thereby locking each other in place. The rows are sealed with adhesive braided glass tape 10 mm wide and 4 mm thick (0.39"x 0.157") stuck to the tongue side. The weight of the parts will press the seal down to half the original thickness. The same goes for the vertical ends, tape on the tongue and pressure is applied to compress the tape and lower the part into place as the photograph shows. Note the groove is 2 mm deeper than the tongue is high, each block is resting on the sides, not on the tongue.

The exit hole to the chimney in this build is situated low at the left rear side. Thanks to the fact that this is a bell construction it doesn't matter where at the perimeter the exhaust is placed. To avoid a restriction due to the placement close to the floor and the inner corner the hole is shaped as a funnel. The opening inside is 250 mm (10"), reducing to 150 mm (6") in the thickness of the material. This way, there's plenty of space for the exhaust gases to stream into the exit opening.

The size of the opening for the combustion chamber in the inner skin is determined by the inner dimensions of the firebox/combustion unit. The front end of the firebox walls fits snugly in a rabbet of the inner skin. In this way, the front of the firebox is supported by the inner wall, the rear of the combustion core is supported by the adjustable metal frame pictured earlier. The perimeter of the firebox opening is sealed with superwool in the inner skin's rabbet/groove.

The left and right sides of the inner skin's opening are chamfered at a 45 degrees angle in order to obtain space for a wider door and a better view of the fire. The detail about fixing the outer skin in the U shaped steel is clearly seen in the drawing above and picture below. The next photo shows how the outer skin is assembled. There's also a superwool seal between the door frame and the inner skin, as is visible as a white line in the photograph.

The configuration of the secondary air supply which generated the best results was found through a lot of experiments. Twelve different combinations were tested, variables such as horizontal and vertical tube sizes along with the shapes and lengths of the air outlets were investigated. The next photograph shows five of those combinations. All of those are affected by corrosion, some more than others. The model which will be in use in this particular heater is the second from right, the final version used has a slightly shorter vertical tube. The vertical part of the tube in the middle is a round tube and as such similar to Matt Walker's pre-port tube.

The secondary air supply (the floor channel) is fitted in a recess in the firebox floor, in fact the fire is on top of it. See the photo of the completed core if you're unsure about where the floor channel is situated. The primary air inlet (via the flap on the door) as well as feeding the main fire also feeds air into the secondary air channel situated directly behind it. This primary air inlet too is situated low in the door (see photo). As the temperature of the air entering is very much lower than combustion chamber environment it will naturally remain low (cold air falls, in this case 'cold air stays low') and therefore the secondary air tube is fully supplied with air at all times.

The hotter the environment, the more air is streaming into the floor channel. The duct itself is heated up by the fire which in turn pre-heats the incoming air. The triangle shaped opening at the top of the vertical part injects the air at halfway height in the port.

At the front side of the combustion chamber a steel plate is mounted which diverts the rest of the air upwards. Because of this provision the fire burns a bit more calmly and the chance to get a hefty CO-spike is reduced. See for this provision the relevant drawing in the "Designs" chapter.

For a temperate sea climate this is a large heater equipped with a surprisingly small combustion chamber. With this design it is not needed to employ "tricks" like crisscross logs or "camp fire style" wood loading (used to lessen smoke and aid burning by incorporating lots of air in normal heaters). Such methods are not only no longer needed, but also lessen the load capacity. Just load the box, fuel laying front to back and it will naturally have enough air, caused by the irregularities of the fuel.

One full load in this 150 mm (6") system size heater would weigh in at about 6 kg (13.2 lbs) bone dry medium sized birch logs. The best results with this loading style and floor channel as drawn will be obtained by a top down burn. When lit at the top of the whole batch as far back as possible, a small kindling fire will eat through the whole pile by itself.

Depending on the fuel size and the chimney draw the burn will last between 55 and 90 minutes. The chimney temperature, measured in the centre of the chimney pipe won't get higher than 80 ºCelsius (175 ºF) when the heater is started cold. When the heater is fired a couple of days in succession the highest temperature in the stove pipe will be around 120 ºCelsius (248 ºF). In that last case it is recommended to use larger diameter fuel because the chimney draw will be quite a lot stronger.

All molds and castings, excluding the castings of the core, are made to order by Bergkachel v.o.f. in The Hague, Netherlands. The 3D drawing in SketchUp 2016 format of the complete design is downloadable through this link.

Drawing updated 10/05/2016.

Batchrocket central heating boiler

The design outlined here is made and built by Rémy Bakker, living in the north of Limburg, Netherlands. He lives in the vicinity of the Reichswald in Germany, his nickname is "Holtere", which is an old expression for "woodlot". The whole history of his heater(s) are described in a thread on the Ecologieforum titled "Update bouw houtkachel". It's in Dutch only but lots of pictures are included.

Note: the following is for illustrative purposes only, a system as complex as this should only be undertaken by those competent to do so.

"Our heater is not centrally located in the house and we need quite a lot of heat for the in-floor heating of the rest of the house outside of the living room. In fact, the living room is thoroughly insulated and is a recently built annex to the 1920-ish house. A warm water appliance could be incorporated so this is how the choice for a central heating boiler was made. Connected to a couple of large solar water heater collectors and a similar sized storage of 1000 liter (35 cu ft). The pump starts running when the water temperature in the exchangers is over 75 ºCelsius (167 ºF)."

Some figures:

RBB wood heater for an unpressurized system.

Dimensions of the heater: W x D x H= 48 x 75 x 157 cm (1.57' x 2.46' x 5.15').

Systemsize of the RBB is 150 cm2 (23.3 sq.in.) or 138 mm (5.43") diameter, chimney connection 150 mm (6") diameter.

Internal size of the firebox: W x H x D= 20 x 30 x 50 cm (7.87" x 11.8"x 19.7").

Maximum load 6 kg (13.2 lbs) beech per cycle of 45 minutes.

Heat release directly to the room estimated 2 to 4 kWh (6820 Btu up to 13600 Btu) maximum.

Externally, the sides get to between 60 and 75 ºCelsius (140 and 167 ºF), the same as the water temperature, the rear wall a bit warmer. The front, together with the door becomes hotter, especially the top half (maximum 180 ºC (356 ºF)). This could be lowered when the inside is insulated.

The heater is able to heat the 1000 liter (35 cu ft) water storage up to 75 ºCelsius (167 ºF). When the return temp rises past 75 degrees, firing should be reduced to prevent boiling noises and for safety reasons. A way to counter this effect is to enlarge the exchangers, more volume means it will take more time to get the water to boiling point.

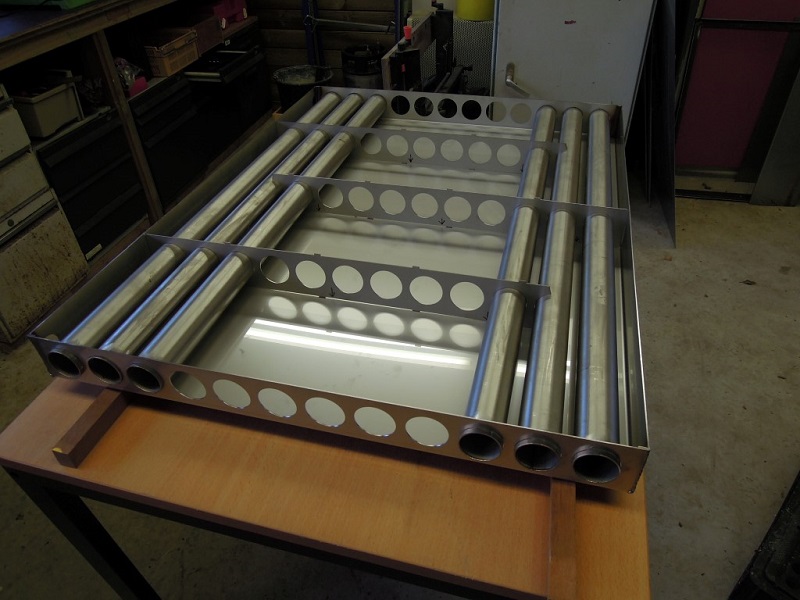

This could be done by using fewer fire tubes and/or making the exchange panels wider. For example with 11 fire tubes instead of 12 like in this implementation. The sides of the exchangers inside the heater could be insulated. As it is now the water is heated up from two sides, from inside the heater above the firebox and inside the tubes.

Unpressurized systems are more prone to boiling noises as compared to pressurized systems where the boiling temperature can be as high as 125 ºC (257 ºF). The large side panels of this heater are not designed to tolerate more than "normal" pressures, so this system operates at normal atmospheric pressure.

The lower part of the heater is made out of stainless steel because of condensation fluid, which is acidic and could cause corrosion. There's no drain for condensation fluid but this could be done later.

The exhaust gases are coming down through the exchangers on both sides of the ash drawer and stream to the back where the chimney pipe starts. The ash drawer hangs on a couple of rails and is shorter than the depth of the heater. This way, there's always space enough for the gases to stream to the exit hole. In this construction it isn't necessary to make the ash drawer airtight because there's a second p-channel on the slit in the floor of the firebox.

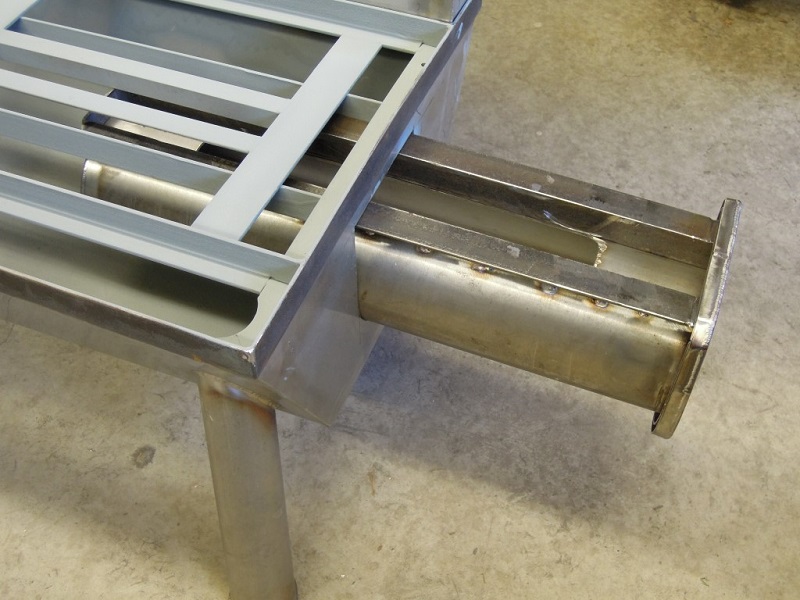

The size of the heat exchangers is 99 x 75 x 7.5 cm (39" x 29.5" x 3"). Each of them contains 12 fire tubes sized 48 mm diameter x 2 mm thickness. At the bottom the tubes are sticking out slightly, to encourage condensation fluid to drip down. The exhaust gases of 900 ºC (1160 ºF) from the rocket core stream down through the fire tubes. The water, contained in the panel around the tubes streams from the bottom up. Internally, there are baffle plates that force the water to take a more circuitous path on its way up through the panel.

The top of the heater is double skinned with a space of 20 mm (0.79") at the sides and 30 mm (1.18") at the top between the skins. This space is completely filled with superwool to insulate the living space from the very hot inside of the heater.

Pieces of vermiculite board are mounted directly above the riser to protect the steel from overheating. The temperature at the outside of the heater's top is around 50 to 80 ºCelsius (120 to 175 ºF), more or less the same as the sides of the heat exchangers.

The riser is built of split fire bricks of 30 mm (1 1/4"). All those are cut to an angle of 67.5 degrees on both the longest sides, together they form an octagon riser.

The riser parts are glued together with stove caulk and secured with welding wire. To help maintain strength the joints are staggered, so achieving a running bond.

The riser as a whole is secured and insulated with a mix of vermiculite and clay.

The firebox is built out of fire brick boards of 30 x 30 x 4 cm (12" x 12" x 1.57").

The sides of the firebox are also insulated with a layer of superwool. This is done to prevent the firebox from losing too much heat to the exchangers. As always in rocket heaters we lose as little heat as possible from the combustion itself which is an essential part of their efficient operation.

The picture above shows clearly the position of the second P-channel. In a later stage it is clad with vermiculite board, it serves as a lid on the ash drawer as well.

Exhaust gas temperature without turbulators between 80 and 120 ºC (175 to 250 ºF), depending on the water temperature. As can be clearly seen, after the heating season the riser is completely white on the inside and the fly ash on the exchangers is just faintly brownish.

With turbulators (chains with 6 mm (0.25") links) the exhaust is the same as the water temperature, maximum 75 to 80 ºC (167 to 175 ºF) measured in the center of the chimney pipe.

A drawing of the heat exchangers are available through this link.

Pizza oven / terrace warmer / pool heater combination

The design outlined here is made and built in 2015 by Tom De Smedt, living in Genk, Belgian Limburg. This article is very much the same as his thread at Donkey32's Rocket Stove Forum and included here with his permission.

Note: a system as complex as this should only be undertaken by those competent to do so.

"After setting up a swimming pool in the garden, and finding out that there isn't much fun in keeping a cold pool tidy that nobody's swimming in, I started playing with the idea to build a wood burning pool heater. Much and most examples on the internet, YouTube DIY versions as well as commercial ones, seemed to be rather smokey contraptions, not to mention dangerous ones, and often plain ugly. Then I stumbled upon the rocket stove technology, and spent quite some time reading up, and thinking about how to use it in an aesthetically pleasing way.

I decided I was going to build a rocket powered pool heater, but given the fact that it would be a time consuming and rather bulky, not to mention costly project, I wanted to have a safety net, in case the pool heater didn't perform as desired. This made me come up with the idea to integrate a pizza oven with a swimming pool heater. When pool performance would be laughable, I could always continue enjoying the pizzaoven part.

In the end, this resulted in the build I would like to show you all in this thread. It's proven to be capable of heating my 16000 liter (565 cu ft) pool from 20 to 30 °C (68 to 86 °F) in 24 hours of wood burning. I did the math, and this would mean that on average, the heater is giving off 10 kW to the pool, which pleases me a great deal. During the building process, it has already served many a pizza, and a few roasted chickens as well.

Given the fact that my wife accepted it, I think it is fairly pleasing to the eye as well, but I will leave that judgement up to you. If anyone would like to attempt the same, I hope they will find inspiration in the following pictures."

Step one, foundations. Note the pool pump in the background, essentially to the workings of the water heater.

Step two, insulating the base with portland cement / vermiculite mix.

Step three, buying a second hand stainless steel boiler and cutting split fire bricks into parts for a riser and a batch box. Note the final layout happened to be slightly different, in that the boiler is behind the riser.

Step four, assembly of the batch box rocket on the foundation, using refractory mortar, and after curing, lighting it. => first success!

Step five, bricklaying and dividing into two compartments with a stainless steel plate.

Step six, insulating the rocket stove with vermiculite and creating an oven floor with t-bars and 4 cm thick concrete slabs. T bars were given room for expansion. All in all, maybe not the best technical option, but wanted to keep footprint as small as possible. The black soot on the backplate is from previous firings.

Step seven, insulating the concrete slabs with vermiculite /portland cement mix, and laying refractory tiles. Not much space between the walls and the start of the dome, I know. (small footprint remember) I "insulated" that with 5 layers of aluminum foil, which in the end proved sort of satisfactory. The wall heats up to the point where you can't keep your hand to it for more than a few seconds, but the good thing is that sitting beside the wall in the evening is rather cosy and comfortable.

Step eight, creating a mould for the dome, and building the dome.

Step nine, taking away the mould, and cutting and installing refractory front and rear walls.

Step ten, bricklaying on a second mould, restarting over and over. Until in the end I had an arch at the front and a closable opening in the back which has the same cross section as the flue, 150 mm diameter. The top of the rear opening is flush with the oven ceiling, to minimize flue gas obstruction.

Step eleven, closing the opening with a brick and testing the oven. (beer in the butt chicken)

The oven stood in this stage for quite some time, until I could figure out how I would insulate the walls of the boiler compartment at a reasonable cost, and with good efficiency.

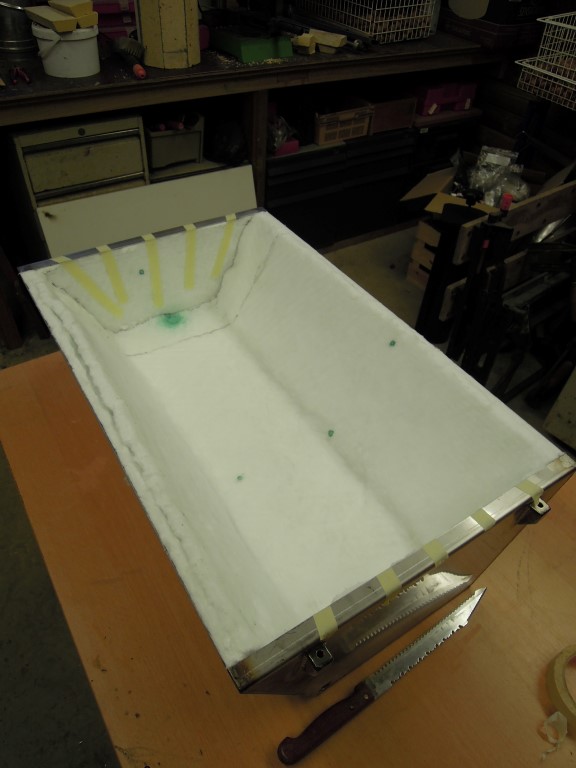

Step twelve, bought a roll of superwool, and created a skeleton I could tie the insulation to and put around the boiler.

I also created a condensation fluid collecting tray from the bottom of the outer shell of the boiler, that I cut off. The outer shell was not stainless steel, so I hesitated to use it for this purpose, but the metalworker who welded the piping to it assured me that I would not see it rust to shreds any time soon. (of course stainless would have been the better option anyway... time will tell)

Step thirteen, installing the boiler onto sort of a pedestal, so I would be able to clean out the ashes collecting in the tray.

Step fourteen, filling up the edges of the compartment, to avoid shortcutting of hot flue gas to the exhaust. I used cutouts from the outer shell of the boiler for this, and plugged it at the top with superwool.

(Editor's note: not really necessary, because of the down draft of the gases)

Step fifteen, closing off the top of the boiler, keeping some headspace and insulating it. The longer pipe stub at the top of the boiler is the cold water tube which is reaching down inside close to the bottom, the shorter one is for extracting the hot water close to the top. Between those, there's a thermocoupler probe so the temperature of the water can be monitored. See this small png how this looks like.

Step sixteen, closing up the rear and connecting stainless tubing and PVC pool hoses, surrounding the top with some extra aluminum foil for good measure.

Step seventeen, I covered both the top of the dome and boiler compartment with vermiculite / portland cement mix, to insulate and make it gas tight. Then I bought and installed a second hand insulated stainless steel chimney, and bent some sheet metal and used some leftover insulation to produce two front covers for the oven and the batch box. Stainless steel handles were bought from IKEA.

That's where I'm now. I still need to cover the build with a stainless lid, or a bluestone slab, I'm undecided as of yet. I also have some grouting left to do.

(In order to avoid rantings about the dangers of heating water with fire, and possible pressure buildup and so on, I will mention that I consider this design as safe, since the boiler is connected to the pool and pump unit without any valves or obstructions. My pool filter pump is programmed to pump filtered water through the boiler for 15 minutes, every other 15 minutes. In case the power fails, I can always open up the pizza oven door, and close off the back window, to stop heating the water, and avoid melting my hoses with boiling hot water. In the event of failure at least the boiler is outside and not in a dangerous position as it would be in a basement.)

Regarding oven temperature, I have no means of measuring it (yet), but Sunday evening June 25th 2015, the dome and oven floor were absolutely clean, not a speck of soot, or spilled cheese remaining anywhere. I've been led to believe this starts to happen when the walls are between 370 and 400 ºC (698 and 752 ºF).

When I started cooking with the boiler installed, I did notice that the initial heat decreased more quickly than in the past firings, when the back window was closed off. I guess that's not too surprising, plus it's all relatively speaking, the 8th pizza was still ready in under 4 minutes :)

I should mention that, due to the heat, one crack formed in the outside brickwork during one of the first firings. The crack is slightly larger when the oven is hot, and reduces again when the oven is cold. It doesn't seem to get any worse, so I guess it just means it has created its own expansion joint. Better design on my part might have avoided that. If I would redo this, I would not rest the T bars on the outer wall, but on an inner wall, not touching the outer skin.

Step eighteen, the brickwork was grouted around half of July 2015 and I fabricated a sloped, painted hardwood cover for the oven in order to agree more with the theme of the house.

Around the batch rocket the insulation is loose vermiculite, in hindsight it would be better to stabilize this with a little bit of portland cement or clay.

Open systems, without door, p-channel or floor channel

Between July 2017 and June 2018 I designed a number of open systems without a door (and hence) no provision for secondary air. Don't expect those systems to be comparable with closed systems efficiency-wise, the excess air factor is much too large for that. Although there's a strong indication that these heaters are just as clean burning as their higher efficiency brothers.

Please be aware that a heater with no door isn't recommended inside a house. Due to the fact that in essence it is an open fireplace, it could spill smoke inside the living room. Also, no door means the heater can't be closed which could be dangerous while people are asleep. In case the fire isn't completely out, deadly carbon monoxide could spill out of the heater due to weather changes for example.

1: Münster, July 2017

The first open system was mounted inside an art sculpture designed by Oscar Tuazon which was built at the same time during the decennial Sculpture Projecte Münster of 2017. The term ‘open’ has stuck when describing this system. The concrete sculpture was built in the outside air aside a canal and meant as a space for people to hang out. With the possibility to light a fire in the firebox to warm up the concrete column. Which can be very comfortable to lean against during chilly evenings.

The firebox was a 250 mm system cast as a cylinder to match the hole in the concrete column and set horizontally behind the opening, the riser was cast with an octagonal cross section. The circular firebox' front opening had exactly the same cross section area as the rectangular front opening of a 250 mm system according to the recommended proportions. The riser in the picture appears to be very short, another piece of equal length was placed on top.

The concrete cylinder being hollow with a closed top served as a single bell of hefty weight, 6 metric tons. The chimney was mounted inside, starting 40 cm above floor level and protruding just 30 cm out of the bell’s top (not visible in the picture). The riser had the normal back sweep (the ramp at the bottom rear of the riser).

picture © Henning Rogge

2: Free University, Brussels

The second open system was built in the courtyard of the Free University of Brussels (ULB) during April 2018, done as a workshop for and by the students. It was a brick 200 mm system set inside one large brick bell. In outside air again, an inner courtyard on top of a parking garage. What makes this build interesting is that the back wall of the bell was actually an existing wall of a neighbouring building.

To prevent excessive loss of heat into the large wall, the back wall of the bell is insulated with 25 mm of Superwool. Building the structure according to the recommended values means that the bell is very spacious, even much more spacious than expected. The riser layout was done like the Mallorca build, square, out of split fire bricks, no back sweep, only the chamfered corners at the rear of the riser up to a level as high as the port. Please read about the consequences of a square riser as opposed to a round one in the "Building" chapter.

The results, although not tested with a gas analiser, were very encouraging. It worked without too much persuasion just one hour after completing the build. In fact two ladies were still doing pointing work while it was getting dark and the heater was fired up. A lot of water vapour came out the short chimney and after an hour this disappeared completely. The drawing in Sketchup 8 format can be obtained here:

The next morning a video was taken, sadly without the impressive low rumbling sound that gives these heaters the name of Rocket Heaters.

3: Maureen Paley, London

Another one was done in the art gallery of Maureen Paley in London in June of 2018. It consisted of two stainless steel barrels on top of each other and a combustion core built out of insulative refractory board.

This heater is a system size of 120 mm, so the riser is a square with 120 mm sides (with the remaining values taken from the tables for a size of 120mm). It's built inside a partially open courtyard as an addition to the opening of the art exhibition called Fire! by Oscar Tuazon.

The flue is simply a straight pipe inside the barrels, starting about 20 cm above floor level. It performed very well although at the time it could only be run with small pieces of fuel. No further testing has been done on this one.

All three of the above projects were initiated by Antoine Rocca, docent of architecture at the Free University of Brussels (ULB).

Materials

Concerning materials, there's quite a choice. Firebrick, refractory castable, clay - combined with each other or secondary materials.

(read more)

Metal

When thinking about a wood stove, people tend to picture a box stove of whatever shape. But metal isn't a good material for a Batchrocket, for the combustion core at least. The environment in there is agressive enough for rapid decay.

(read more)

Dimensions and scalability

The most frequently tested version is the one with a riser diameter of 150 mm (6"). But a range of other sizes are perfectly possible.

(read more)

Sizing a batchrocket

How to determine the required system size for a given space.

(read more)

Building a brick core

Being a specialist isn't required in order to build this core unit. With some technical insight, and materials which are relatively easy to come by in most places, a good result is entirely possible.

(read more)

Casting a core

Possible using refractory castable, a material which consists of aluminum cement and among others ground firebrick as the aggregate. Molds need to be build and the material need to be mixed using as little water as possible. Also, a vibrating table is required to condense it in order to get the air out.

(read more)

Bell theory

The word "bell" will be mentioned in the "Applications" chapter quite often. This article explains what it is, how it works and what it is being used for.

(read more)

Bell sizing

How large a bell can be relative to the combustion core is quite important, as is scaling up or down.

(read more)

Materials

In order to build this combustion unit a lot of combinations are possible. For instance, using fire bricks, whether or not mortared with real fire cement or a mix of clay and sand. The thinner split fire bricks or plates held together by a steel frame is another possibility. Casting in a mold of refractory castable (fire concrete) offers other benefits (and also other problems, unfortunately).

Some people used a mix of clay and sand with a little bit of portland cement added in order to obtain a firm core before the thing is fired. When the cement gives up eventually because of the temperature the clay should be reasonably strong by then. A couple of those cores are built entrely out of clay with short natural fibres mixed through for strength. And last but not least: insulating fire bricks, those are ideal from the combustion point of view. Very little mass to heat up and very insulating but have a vulnerability to abrasion as a disadvantage.

Non-insulating constructions (remember, mass doesn't insulate!) should be insulated from the outside. This insulation could be anything as long as it is heat resistant. Expanded perlite or exfoliated vermiculite are fine, especially the somewhat coarse kind mixed with a little bit of clay and some water to prevent sagging. But also ceramic blanket like Superwool is an excellent material for this purpose. Somewhat less known but surely fitting for this purpose are expanded and fired clay granules normally used for hydroculture like Leca.

All these structures could piece by piece lead to an appliance which works really nice and yields spectacular results. Of course a plethora of choices and combinations are possible so there're a lot to choose from.

Metal

Concerning metal in constructive parts: this will lead inevitably to disappointment, it doesn't matter whether it is steel or stainless steel. In an environment sporting temperatures higher than 760 ºC (1400 ºF) combined with substantial excess oxygen and carbon frugality every normal available kind of steel will corrode at a racing pace. After every burn flakes and slices will fall off and in a foreseeable span of time a hole will emerge at the hottest spot. This process is known as spalling, the flakes are dull grey, light weight and almost non-magnetic.

One of the ways to avoid this is keeping the temperature low by leaving out insulation around the hottest spots but that compromises the complete combustion. Another way to let the steel survive is to shield it from air, no oxygen no corrosion. But that is asking for expensive fire resistent coatings or a very small air supply so there isn't enough oxygen left to react with the steel. This last possibility is hard to achieve because by starving the fire of oxygen the quality of the burn is compromised which will result in incomplete combustion once again. However, for some parts the use of steel could be feasible, I'll come back to that when it's appropriate.

Dimensions and scalability

The bulk of development has been done in 2012. The experimental model was one with a 150 mm (6") riser diameter or equivalent. Even back then people asked me for smaller or larger versions of this thing. Jim from Blacksburg, Virginia wanted to build a smaller one, no more than 100 mm (4") riser diameter. Measurements of the 150 mm system were available and with this in hand Jim worked out a scaling method. He found out the common factor which serves as a kind of base figure, all other sizes are a multiple or part of this base figure.

Up until mid-2016 the smallest working model is Jim's, the largest is built by Radek Stastny from Czech Republic and Alex Harpin from Canada, 220 mm (8.66") examples. As of October 2016, the largest system I am aware of is a 250 mm (10") item, built by Pablo Kulbaba (Pablo OresKu) and Ramiro Walti during a workshop in Las Amalias San Pedro in Argentina. The larger ones are somewhat more consistent in performance compared to the smaller brothers but results are good along the entire line. The base figure found by Jim is 72.34% of the riser diameter.

The riser can have a shape that is not the 'perfect round or octagonal' cross section, contrary to long held belief. It can, for example, be square, tried and tested in combination with a floor channel only. Having a square shape is much cheaper and easier to build so this discovery is of great benefit and interest to all Rocket Heater builders. The natural action of the exhaust gas (particularly with the half-octagonal shape of the riser where the gas enters through the port giving the initial swirl) is to assume a circular column shape as it rises. When using a square riser, it must be made larger than a round riser in terms of cross section area, and it must be large enough that the circular exhaust column can fit inside the square without obstruction. Essentially the corners of the square become 'dead space' that do not contribute to, or detract from, the formation or perpetuation of the circular swirl of the exhaust gas. So when sizing the square it means that what was the diameter of the circle becomes the internal dimension of the square. A rectangle is still not considered to be a good shape. As it does not add any benefit in terms of cost or ease of construction over a square it should be ignored.

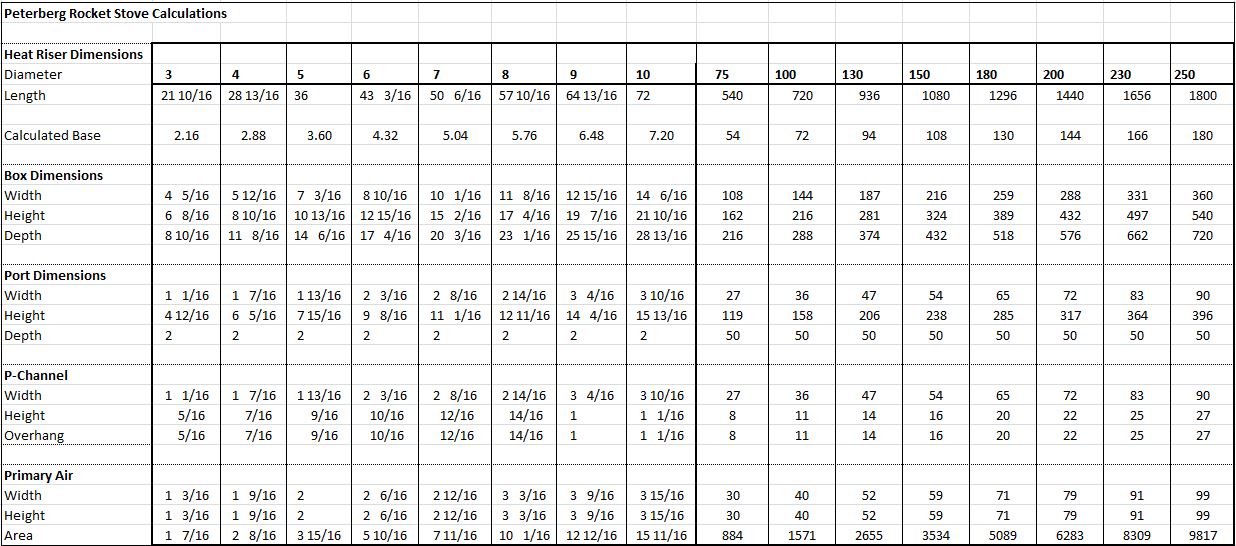

Both in the Netherlands by Ritsaert Snijder as in the USA by Doug Ptacek spreadsheets are made whereby only the system diameter need to be known and the rest of the dimensions rolls out. The spreadsheet is available here. Tables are also available, there's no need for a computer at the muddy building site, a print on a piece of paper is sufficient. Below is Doug's table, both in inches and in millimeters.

Keep in mind that the riser should be the same diameter as the chimney size. Larger chimneys will work, smaller ones won't.

The batchrocket dimensions can also be calculated by hand, because the formula is very simple.

There is a common base number to which all the other dimensions are related. That base number is derived from the diameter (fictional or not) of the riser as explained above.

Base dimension is 72.34% of riser diameter.

Width of firebox is 2 times base.

Height of firebox is 3 times base.

Depth of firebox is 4 to 5.5 times base.

Height of port is 2.2 times base.

Width of port is 0.5 times base.

Height of the riser is 8 to 10 times base, measured from the firebox floor. The firebox floor does consist of a narrow flat surface the width of the port. Left and right there are 45 degree slopes in order to concentrate the glowing charcoal in the middle. Those 45 degree chamfer is part of the dimensions of the firebox. In addition, there’s also a similar shaped piece at the rear bottom of the riser.

The total air inlet is 25% of riser cross section area.

P-channel is 5% riser csa.

Main inlet plus an optional window wash is 20%. Main inlet could be larger when starting cold and is situated level with the floor of the firebox.

P-channel should be as wide as the port or slightly more, for the calculation of the 5% you should take the width of the port, not the actual width of the duct. This duct is hanging over the top of the port the same distance as the depth of the duct.

The back of the p-channel which is resting against the firebox rear wall has been cut away over the height of the overhang.

How to size a batchrocket

Yasin Gach, the translator of the French version, provided a spreadsheet for to calculate the system size of a batchrocket for a given space. It's indicative, not absolute, but it'll give a good idea of the necessary size. The following article is Yasin's, the spreadsheet is available here.